04/04/2024 – Joining / welding

High-quality, reliable, durable welding machines

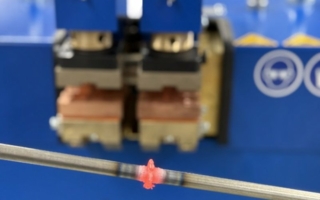

On 120m² of exhibition space, 20 welders for different applications will be on display: electric buttwelding machines for steel, copper, aluminum or brass, for solid wires as well as for stranded wires and conductors. Cold welding machines for non-ferrous wires will also be presented, as well as special welding machines for thin steel strips.

As a globally active family business, Strecker is the first point of contact for individual complete solutions in welding technology and will once again be represented with a stand at "wire 2024" in Düsseldorf. For more than 90 years, they have been developing, producing and supplying high-quality, reliable, durable welding machines for a wide range of applications in the wire and cable industry.

In many applications, especially when processing steel, annealing is an important part of the joining process. With the "V30 smart" welding and annealing control system, the company offers customers the option of adapting not only the welding process but in particular the subsequent annealing process to their specific requirements.

But why is annealing necessary at all?

Annealing, a heat treatment, is crucial for the modification of material properties. In electrical resistance buttwelding, hardenable steels undergo a structural change in the heat-affected zone. A controlled, multi-stage annealing process, in particular soft annealing, reduces existing precipitates of cementite or pearlite. This ensures the required material properties for the subsequent production process. Typical temperatures are between 650°C and 750°C.

Now the question arises: What are the different alternatives for annealing?

On one hand, there is manually controlled annealing: the operator presses a button until the desired annealing colour is reached, whereas in manual annealing with a time relay, the annealing time is controlled by an adjustable relay. A more precise and program-controlled option is annealing with the "V30 smart" control unit.

What are the advantages of the "V30 smart"?

The "V30 smart" combines proven functionality with intuitive user guidance by means of a rotary push-button and a large 7-inch display.

The IntUSB and Ethernet connections make it quick and easy to exchange welding programs between the control units. They also allow uncomplicated archiving, editing and management of welding programs.

Another advantage is that existing welding programs from previous control units can also be transferred.

Annealing can be time-controlled in up to three segments. This means that even the most critical materials can be optimally post-processed. Furthermore, the thermal post-treatment of high-carbon steel or special alloys can optionally be optimised by using pyrometers. Up to five segments can be used for precise control, accompanied by a graphic display of the temperature in target and actual curves. This ensures outstanding process reliability.

The “V30 smart” controller can detect and compensate for voltage fluctuations of ±8%. The mains frequency is automatically detected. Sensitive areas such as the programming level can be protected against unauthorised access by assigning a password. The free naming of the welding programs allows the user to use company-internal designations, for example alphanumeric in (mm) and (inch). Conversion from the predecessor models “V12”/“V20” to the new "V30 smart" is carried out by replacing the control unit.

wire 2024, hall 10 booth A 21

August Strecker GmbH+Co. KG

Elektro-Schweissmaschinen-Fabrik

Jahnstrasse 5

65549 Limburg, Lahn/Germany

Tel.: +49 6431 9610-0

sales@strecker-limburg.de

www.strecker-limburg.de