14/12/2020 – Inspection and sorting of plastic pellets

Guarantee for visually and functionally perfect products

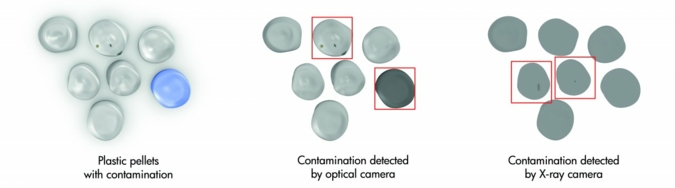

Black specks and color deviations often lead to increased scrap rates in the production of plastic injection molded parts, but also in the manufacture of profiles, cables and pipes. The same applies to metal inclusions in the pellets, which leave traces in the end product and the processing machines and cause costs.

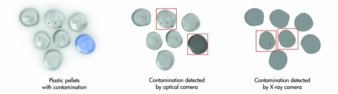

Examples for plastic contamination (left): The optical cameras detect visual defects on the pellet’s surface as well as color deviations (center). With an X-ray camera, metallic contamination inside the pellet can be detected (right). © Sikora