19/07/2022 – EMI shielding effectiveness on a wide range of frequencies

Graphene-based PVC

The compounding industry plays a key role in tomorrow's world, as its raw materials are supplied to strategic sectors such as cable, automotive and construction. It is also the answer to the many challenges that arise as technology advances and encounters new bottlenecks.

Human-made and natural electromagnetic interference (EMI) sources can cause temporary disturbances, data loss, and failure of electronic devices, equipment, and systems. These problems create many challenges and are of critical importance to the aerospace, defence, medical, and automotive industries. In fact, EMI has risen immensely due to the exponential density growth of electronics, which may degrade device performance, and adjacent systems.

Miniaturization has further aggravated the EMI issue as mutual interference among components (e.g., cross talk among to subjacent cables) can produce microscopic interference effects. This impelled the development of suitable countermeasures to suppress (or eliminate) EMI effects.

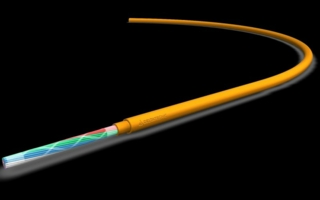

Current solutions for cable shielding can be rigid and heavy tight meshes (braiding) or highly overlapped and expensive metal based foils (made from aluminium or copper) that may be modified with additional tin-, nickel or even silver-plated treatment getting a more expensive final system. These kind of materials are by far the most common materials for EMI shielding owing to their high electrical conductivity. However, many disadvantages were identified such as high reflectivity, corrosion susceptibility, weight penalty, high carbon footprint, and uneconomic processing (since they are time and energy intensive).

Simultaneously, everyone is familiar with commercial semiconductive carbon-based XLPE, which is used for homogeneize the electric field of high voltage AC and DC cables (HVAC and HVDC, respectively) but that is unsuitable to be used for EMI shielding purposes unless one may use an impracticable thick cable jacket (with 3mm or more).

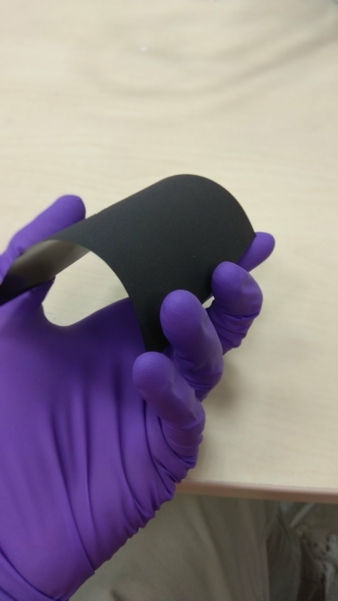

In this consideration, graphene-based compounds have attracted enormous attention due to the unique combination of electrical, thermal, dielectric, magnetic and/or mechanical properties suitable for efficient electromagnetic shielding response.

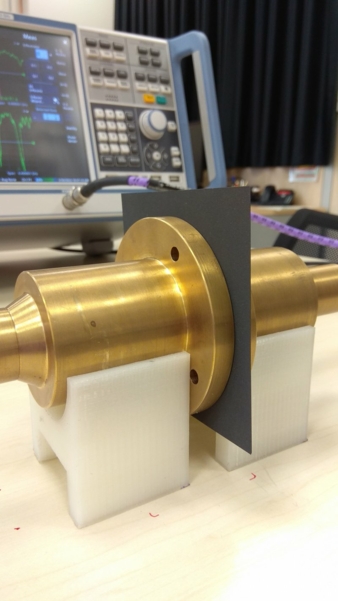

Materials based on multi-layered graphene sheets aroused interest due to their unique properties. Recently, Graphenest teams up with Delta Tecnic to use the fascinating and promising properties of these carbon sheets while co-developing graphene-based compounds for electrical and, particularly, electromagnetic shielding applications. The use of graphene, with a large aspect ratio and high conductivity, provides excellent EMI shielding effectiveness on a wide range of frequencies, especially at high and very high range, essential for 5G and 6G new generation of communication establishment.

This materials opens the unprecedented possibility of producing shielded energy and data cables more rapidly since a partial (or complete) replacement of the metal braiding (e.g., th amount of braid coverage over the wire may be less than 50%) speeds up the production at least 40 times (extruding at a velocity of 200m/min instead of braiding at 5m/min, for reference), while generating a lot OPEX savings.

The authors are Bruno Figueiredo and Eva Gotor.

Delta Tecnic

Pol. Ind. Molí de les Planes

Carrer Rec Molí de les Planes, s/n

08470 Sant Celoni, Barcelona, Spain

Tel.: +34 938 674 284

deltatec@deltatecnic.com

About Delta Tecnic

Delta Tecnic was born in 1982 to commercialize raw materials in the plastic, cable, ink, paint, and cosmetic industries with the distribution of leading brands worldwide. With more than 40 years of experience and a total of 20,000m2 in facilities, with three production plants, two of them located in Barcelona (Spain) and one of them in Querétaro (Mexico), Delta Tecnic has grown to position itself as a company leader among Trading companies in Spain, as well as one of the main producers of Masterbatch for the cable and PVC industries globally. Among the three divisions of Delta Tecnic, DeltaColor Masterbatch stands out, whose production capacity reaches 18,000t/y. In addition, the division has more than 11,000 developments and 22 production lines. On the other hand, the Delta Trading Pigments and Plastics divisions distribute in leading firms such as Eckart, Cabot, Baerlocher, Cinic, or Aralon. With 3% of global turnover dedicated to R+D, the company is focused on technological innovation and quality of service, providing deep knowledge of the market and formulations, always optimizing customer processes to become a technology partner focused on product development and innovation. At present, it already exports to more than 60 countries with an export volume of 80%, becoming one of the main players in the market.

About Graphenest

Graphenest S.A. (www.graphenest.com) was founded in 2015 and its activity is centered on the development and implementation of next generation graphene-based EMI shielding products. Graphenest is producing graphene through an in-house proprietary cost-efficient clean technology that allows the formulation of products with unparalleled levels of shielding performance at high and very high frequencies.