03/04/2020

Getting things straight

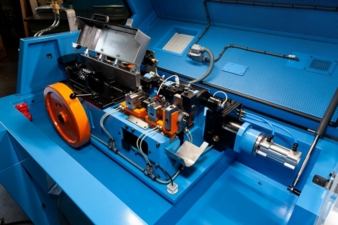

The new “Precision Cut UD0” from Jouhsen-Bündgens uses rotary straighteners to process round material, and can also cut even the thinnest wires with sensitive surfaces precisely and efficiently. Suitable for both short and long sections, it is a truly versatile machine. At “wire”, visitors will be able to see the UD0 live in action.

When it comes to processing wire, Jouhsen-Bündgens are the experts. Based near the city of Aachen in western Germany, the company has been developing machinery for straightening and cutting wire for over 150 years. Customers from around the world turn to Jouhsen-Bündgens for custom-made solutions. Staying in touch with the market helps the business react quickly to new developments. In recent years, for example, customers have increasingly been asking for machinery for straightening extremely thin wire. “We reacted to this by updating a design that was part of our product range until the 1980s,” explains Andreas Kruse, Chief Technical Officer at Jouhsen-Bündgens Maschinenbau GmbH. The next-largest machine in the “UD” series, the “UD2”, struggles with wires that are very thin. On larger machines, the straightened wire has to cross longer open spaces. This can cause very thin wires to bend and deform when being pushed through. With the “UD0”, Jouhsen-Bündgens has successfully created a universal straightening and cutting machine for wires measuring up to 1.5mm in diameter.

Uniform properties for consistent straightness

Thin wires are defined as those with a diameter of less than 0.3mm. They can have a round, square or even hexagonal cross-section. “Straightening wires like this and keeping them straight is a big challenge, especially those extremely fine wires with a diameter of just 60µm,” says Kruse. The important thing is to make sure that the sum of residual stresses in the straightened section of the wire is balanced. This ensures that the wire will behave predictably during further processing. Rotary straightening is one of the few processes that can achieve this. Kruse explains: “Rotary straightening aims to create balanced material properties.” Although roller straightening is sometimes more gentle to sensitive surfaces, it is often not suitable for this specific goal.

Rotary straightening of thin wires

In roller straightening, the wire or pipe is transported from the spool by an uneven number of rollers arranged at an offset. This bends the wire and ensures it comes out of the machine straighter, given the correct deflection.

Rotary straightening works differently, as the straightening tools rotate around the wire. The wire is drawn continuously through the straightener and is therefore processed across the entire surface. This results in much more uniform material properties that guarantee straightness and consistent quality in end products. Given the increasing level of automation in the production of surgical needles, for example, precise wire and pipe sections are essential for accurate and efficient manufacturing.

Easy handling

So is the UD0 just a smaller version of the UD2 or a new version of the old UD0? The basic function and straightening system are similar on both machines. The main advantage of the UD0 is that its modified tool operating mechanism makes it easy to access the machine during threading. “We took the proven design and brought it up to date, taking the input from our customers into account,” says Kruse. Just like its predecessor and the UD2, the new UD0 is capable of producing wire pieces of varying lengths of 3mm to 3m. This is thanks to an adjustment mechanism that uses two slides driven by crankshafts. Each revolution of the machine can draw in between 0mm and 70mm of wire. Multiple revolutions make it possible to cut even longer sections precisely. The special clamping jaw system protects the surface of sensitive materials. It is designed to continuously feed wire through the straightener, allowing it to be cut without stopping the machine (“flying cut off system”). Jouhsen-Bündgens prefers a bush-to-bush cut to ensure a straight cut free of burrs. Unlike the old version, the new UD0 features an enclosed machine housing. It generates noise emissions of just over 80dB, making it both comparatively quiet and compliant with the latest CE regulations.

Versatile and individual

From steel, stainless steel and special alloys to gold, silver and platinum, the UD0 is perfect for straightening and cutting thin wires and pipes made from a variety of materials. Perfecting the process means adjusting the straightening tools to the respective requirements. The width of the products, the materials and the required surface finish are all important factors here. “Generally, our customers first want to see what their product looks like when it comes out of the machine,” says Kruse. That is why Jouhsen-Bündgens fits a machine with the right tools in advance in its own workshop. Based on their experience and engineering expertise, the company’s wire processing specialists can be relied upon to find the best combination of tool type and material quickly. The straightening tools are made from materials with varying resistance to wear, including plastic grades (e.g. Teflon, PTFE or PEEK plastics), wood, tungsten, iron alloys or even ceramic. Kruse explains: “Estimations of what represents a good service life vary from customer to customer.” The key to getting the right result is achieving the perfect balance between service life and surface quality. Any straightening tool can be adjusted. “Once you reach the limit in terms of wear, however, you have to replace the tool. Our flexible modular system allows the customer to do this in a matter of minutes.” If they experience a problem, however, Jouhsen-Bündgens is always there to help. “We don’t sell machines, we sell solutions. We offer the full package, from the moment a customer sends us a request with sample part to the finished machine and beyond with service and consulting,” he adds.

What does 2020 hold for rotary straightening?

As wires and pipes get ever thinner, the demands for straightness and surface quality are becoming more and more challenging. “On top of this, the process has to be virtually 100% reliable,” adds Kruse. But Jouhsen-bündgens is not shying away from the challenge. It also offers the UD0 with a rotary straightener with nozzles. This significantly reduces the friction between the wire and the straightening tool, allowing for smoother processing of wires with highly sensitive surfaces.

Jouhsen-Bündgens will be presenting a UD0 at its stand at wire 2020 in Düsseldorf. This is the fourth UD0 to feature the updated design, with the others already proving themselves in customer operations.

Jouhsen-Bündgens Maschinenbau GmbH

wire 2020, hall 11 booth G 51

Industriestrasse 11-13, 52224 Stolberg/Germany

Tel.: +49 2402-102067-0

jouhsen@jouhsen.de

www.jouhsen.de