04/10/2024 – Fully automatic welding machines

Flexible “snake” type mesh spacer production

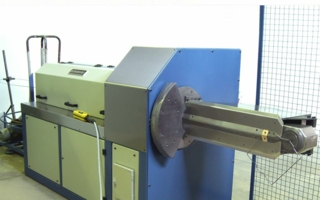

The welding machines of Eurobend in the “PLT B Ladder” series guarantee reliable operation and cost-effective production of “snake” type” mesh spacers from coil.

The sophisticated design of each machine part in combination with the compact lay-out enables minimum changeover times for the different product heights and long maintenance intervals. Depending on the version, the machine can produce spacers with two or three longitudinal wires.

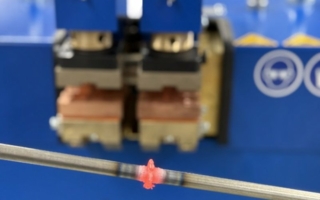

The unique "T" welding heads produce butt-welded spacers that stack perfectly in compact bundles without the need to rotate them, as is the case with conventional overlap-welded mesh spacers. The butt-welded spacers are preferred on the construction site:

– they can be easily repositioned

– do not hook

– no risk of injury due to protruding wires

– are ideally suited for use on foil

Significant material savings! With the 100mm serpentine spacers, for example, depending on the wire diameter, 22% to 33% of the material of the spacer wires is saved by the "T" weld.

The unique bending system (patented) ensures excellent repeatability, perfect product geometry and works in synchronization with the welding process to eliminate idle time during production. The bending system uses pneumatically operated bending units.

Integrated into the bending system, a flexible automatic stacking unit is used to produce bundles with the programmed quantity of spacers during production.

Eurobend's solution for the production of “snake” type spacers is crowned by a fully automatic bundling and strapping station that is fully synchronized with the production flow and eliminates idle times. The finished strapped bundles are then automatically transferred to a buffer table.

The machine offers maximum flexibility in production and is ideal for “just-in-time” production. This significantly reduces the space required to store the different product types.

Eurobend GmbH

Alexander Strasse 1

90547 Nuremberg-Stein/Germany

Contact person is Harris Athanassopoulos

Tel.: +49 911 9498980

sales@eurobend.com

www.eurobend.com