02/04/2024 – How to cope with the future

Flexible energy utilization in heat treatment plants

The awareness of decarbonisation has become obvious to all companies, especially in Europe, in recent months and years. However, achieving the EU’s climate targets is not just about the cost of retrofitting or building new heating systems, but also increasingly about the ongoing cost of production.

Energy costs in particular are very volatile and change almost hourly. The implementation and further development of heating concepts/strategies must therefore also be set as a long-term goal, with the focus on ensuring competitiveness and generating significant competitive advantages. In particular, wire/rod and pipe annealing facilities are at the forefront of this development, as they typically have lower heating energy requirements than other plants, thereby reducing investment costs while utilising the comparatively small amounts of green energy available today.

Electric heating is the first method that comes to mind when talking about decarbonisation of thermo processes. This type of electrical heating, as a stand-alone heating method, has been a state of the art both for continuous and batch-operated heat treatment plants for decades and has its place in the standard repertoire of a every reputable furnace manufacturer. Provided that the electrical energy is generated from renewable sources, the goal of zero-emission heat treatment processes is now within reach. The challenge with this type of heating system is no longer the design of the system, as there are various product-specific, targeted designs on the market, but rather the continuous provision and therefore storage of electrical energy. In addition, the conversion of existing installations to electric heating systems requires a corresponding change in the supply to the system, i.e. the removal of the gas pipes to the burner and a complete rewiring, including the supply of energy to the system by the energy supplier.

However, in order to address these uncertainties and to provide an economical basis for future-proof production with reduced CO2-footprint or zero emissions, alternative concepts such as carbon-neutral fuel gases are increasingly coming into force. For existing plants, switching the energy source from natural gas to carbon-neutral fuel gases such as renewably produced hydrogen is a practical strategy in terms of investment costs, plant capacity and performance or product quality. For these reasons, it is "easier" for many plant operators to switch to green gases then to electrify the process, as most of the peripheral equipment can be retained.

In addition, neutral fuel gas-fired concepts are also an appropriate strategy to overcome the future shortage of green gases, especially H2, until the transition to green energy is complete, since green gases can be added to natural gas as a heating source with gradually increasing contents. The use of green natural gas (Power2Gas) or perhaps in the future of synthetic gases is unproblematic in terms of conversion complexity and process safety. The use of hydrogen is technologically more demanding, e.g., because of the higher combustion temperature and the associated potential for increased nitrogen oxide emissions compared to natural gas.

Therefore, prior to conversion, the effect of increased hydrogen admixtures on the overall system of any gas-fired furnace with different operation modes must be assessed in detail, and several heat treatment processes with continuous and batch operation mode are evaluated for this purpose.

Mobile gas mixing station

In response, Tenova LOI Thermprocess has developed a dedicated mobile natural gas/hydrogen mix-ing station to facilitate the flexible supply of natural gas/H2 mixtures. The station has recently been used temporarily to test annealing processes in a plant for serial production (Fig.1) [1].

The Tenova LOI Thermprocess mobile natural gas/hydrogen mixing station provides the flexibility to supply the required adjustable natural gas/H2 mixtures for a maximum gas capacity of up to 2MW and offers customers and plant operators the opportunity to carry out trials on different furnace types on a production scale.

Experience has shown that an isolated burner analysis is often not appropriate and that, in addition to replacing installed burners with optimised H2-ready burners, the the adaption of existing plants to new concepts should be considered. If existing burners are used, their H2 suitability must be critically assessed. Burner technologies that are in principle suitable for pure H2 combustion in terms of burner life must be evaluated in terms of their emission behaviour and their influence on adjacent parts of a furnace. Tenova LOI Thermprocess’ mobile natural gas/hydrogen mixing station is therefore equipped with advanced process control that tracks all gas flows and other relevant values. Combined with an available high-end flue gas emission analyser for long-term emission monitoring, the way is paved for a complete and sophisticated assessment.

Given current developments in the energy market, the heat treatment plant of the future will have to respond to rapid changes in energy availability and cost, making hybrid heating systems that can use different energy sources a major advantage. Although this advantage is diminished by the initial in-vestment, the flexibility of the energy source can be increased as a function of energy costs while maintaining product quality. Of course, some processes are better suited to this than others, especially when modernising existing plants.

Based on this overview of decarbonisation strategies, a detailed analysis of the boundary conditions and processes is highly recommended prior to new construction or modernisation projects with the aim of minimising CO2 in an economical, technological, and environmentally friendly manner. In the following, a case study of the different heating systems for Roller Hearth Furnace (RHF) annealing plants, as an example for a continuously operated plant, and for a Bell-type Annealing Furnace (BAF) plant, as an example for a batch operated heat treatment plant, is presented to evaluate different decarbonisation approaches for a defined process.

Roller hearth furnace annealing

Purely gas-fired systems are widely used throughout the world and are the state of the art for wire, bar and tube production. For example, for a production capacity of 4 tons/hour of tubes and a target temperature of the annealed material of 920°C, a gas heating capacity of approximately 1.8MW with an average firing efficiency of ηf = 65% must be installed. In theory, higher efficiencies are technically possible, but the rather conservative assumption of 65% corresponds to the state of the art in practice. Because of the inert gas atmosphere, heating of the atmosphere takes place indirectly via radiant tubes.

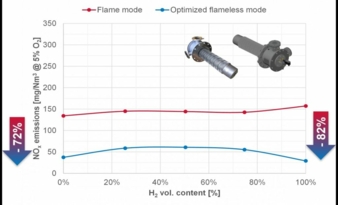

In the case of hydrogen-fuelled plants, the higher combustion temperature and the associated potential for increased nitrogen oxide emissions compared to natural gas must be considered. For this reason, Tenova has developed suitable burners for use in roller hearth annealing furnaces, which have already been successfully tested on a trial basis with 100% H2 and mixtures of H2 and natural gas. In flameless operation, NOx emissions of less than 70mg/Nm3@5%O2 were achieved (Fig. 2) [2].

This technology is already being tested in existing plants and is being prepared for large-scale use. Following successful field trials, it will be possible to heat the plant entirely with H2. This also applies to roller hearth furnaces for wire and bar.

Another option for the decarbonisation and flexible energy utilisation of roller hearth annealing furnaces is to replace the burners with electric heating elements which are separated from the furnace chamber atmosphere by radiant tubes or placed directly in the furnace chamber atmosphere by heat-ing elements or meander heating wires. For a production capacity of 4t/h and a target temperature of the annealed material of 920°C, approximately 1.25MW must be provided, assuming an electrical efficiency of hel =68%. The roller hearth furnace can thus be realised fully electrically heated.

Hybrid solutions are the exception in roller hearth furnaces. From a technical and logical point of view, hybrid systems are easily feasible. One approach would typically be to heat the heating zones in the front part of the furnace chamber with fuel gas and the soaking zones in the rear part with electricity. A flexible hybrid system with a 100% gas-heated furnace and electric heating that can be switched on depending on the price of electricity is another solution. The use of hybrid heating systems has the potential to reduce CO2 emissions or be used as a flexible energy storage system. The systems required are state of the art and need to be individually adapted to the technological requirements of the heat treating process and the infrastructure of the plant owner.

Conventional Bell-type Annealing Furnace (BAF)To date, bell-type annealing plants for wire/rod have mainly been operated using natural gas in order to specifically adjust the mechanical properties of the wire, tube or coil material for subsequent forming processes or the desired product properties required at the end customer.

In this example for a conventional Bell-type Annealing Furnace (BAF), a gas heating capacity of ap-proximately 1.5MW is installed with an average firing efficiency of approximately ηf = 71%.

Tenova LOI Thermprocess “ecoBAF”

Tenova LOI Thermprocess also offers a modern generation of heating hoods with the patented ultra-low NOx HPH® (High Performance Hydrogen) flameless concept with an average firing efficiency of approximately ηf = 76% (Fig. 3).

Significantly increased air preheating temperatures of up to 600°C through an enlarged recuperator exchange area and reduced flue gas losses, result in energy savings of up to 12% and a correspond-ing reduction in the CO2-footprint. In combination with the world's first use of flameless combustion in a BAF, the high NOx emissions naturally occurring at higher air preheating temperatures are significantly reduced to an average of approximately 70mg/m³@5%O2 in the flue gas [1] over the annealing cycle. A special feature of the concept is the spatial distance between the fuel gas injection via special gas lances and the air supply after reaching the release temperature for flameless operation in the heating hood, to effectively reduce NOx emissions.

In the case of bell-type annealing furnaces, Tenova LOI Thermprocess has successfully tested suitable burners both on a trial and an industrial basis with 100% H2 and various H2 and natural gas mix-tures . The burners have special requirements in terms of flame shape and velocity, as the area be-tween the heating hood and inner cover is limited and an inappropriate design can adversely affect the refractory material and service life of other furnace parts. In addition, the latest generation of Tenova LOI heating hoods with the patented “Ultra Low NOx HPH”-flameless concept for bell-type anneal-ing plants has proven its worth. With today’s state of the art equipment, even H2 combustion can be used in bell-type annealing furnaces, with emissions within today’s approval procedures. The “HPH”-flameless concept has demonstrated remarkably low NOx emissions and has proven its worth in the transition towards a stable, low-emission H2 operation on an industrial scale. The concept reduces NOx emissions by more than 75% in flameless mode over a wide range of the annealing cycle com-pared to the flame mode with conventional burners for both natural gas and H2.

Tenova LOI Thermprocess “eBAF”

Another way of avoiding flue gas losses and CO2 emissions is to use electricity directly as energy source for reheating and heat treatment processes. For this purpose, the burners are replaced by electric heating elements or meander heating wires directly in the furnace chamber. In principle, many Furnaces can be completely electrically heated. Fig. 4 shows an example of an electric heating hood with resistance heating.

A key issue is the lower energy density of electric heating systems compared to burners. This in-creases the need for sufficient space in the furnace chamber and the availability of electricity at the plant. For a 1.5MW gas capacity, assuming a combustion efficiency of ηf = 71% and negligible conversion losses of the resistance heating system, approximately 1,0MW of electrical energy must be provided. In contrast, due to the limited surface area, only 800kW can be applied. The reduced heating power affects the heating-up phase of this type of furnace and therefore slightly reduces the throughput of the plant. As less energy is required for the constant temperature during the soaking phases, the reduced power does not affect heat treatment time during these phases. In conclusion, all-electric heating with electricity from renewable sources is a viable way to effectively reduce the CO2-footprint, often with little restrictions on the throughput of a bell-type annealing plant and other thermo processes in general, where the infrastructure for electricity supply is available. Electric heat-ing solutions have been in use for more than 70 years, but have generally only been considered where access to gas is limited due to the often significantly higher cost.

Due to the limited space in the furnace, a fully gas and fully electric heating system with 1.5MW each in a single hood (hybrid heating hood) is technically not feasible. However, electric heating elements can be integrated into a gas-fired furnace with a capacity of around 300kW, acting as an auxiliary element to exploit the advantages of electric power or to cope with the volatility of the power supply. Another option is Tenova LOI Thermprocess “Hybrid-BAF” concept, which allows the use of alternative energy sources. Depending on the availability or cost, electrically heated “eBAF” or gas-fired heat-ing hoods can be used on the same annealing base, to perform the same heat treatment cycle. With this “Hybrid BAF” technology, existing plants can be retrofitted, one heating hood at a time, allowing a smooth transition from today’s gas-fired operation to future all-electric operation, depending on the availability of the energy source.

The use of hybrid heating systems offers the potential to reduce CO2 emissions or to be used as flexible energy storage, allowing the heat source to be changed at the push of a button during pro-duction. The systems required are state of the art and must be individually adapted to the technological requirements of the heat treatment process and to the infrastructure of the plant owner. In general, hybrid solutions for different heat treatment processes are more complex and sometimes productivity limitations have to be accepted for space reasons. In addition, measures must be developed to ex-tend the life of the electrical heating system when it is switched off. Finally, the economics of pur-chasing and maintaining two redundant heating systems must be carefully considered.

Conclusion

These basic considerations show that a continuously operated roller hearth furnace and a batch operated bell-type annealing plant have a corresponding potential for the reduction of CO2, both as a new plant as well as by means of modernisation. Modernisations can easily be done in phases rather than in one go. The investment can therefore be divided into several parts to suit the customer’s specific circumstances. In contrast to new plants, where the investment required is very high, modernising existing plants is a very efficient way of reducing the CO2-footprint in the short term. Often, the additional investment required for more efficient systems is recouped within a few years through energy savings. However, suitable technically and economically optimised solutions can only be found after a prior analysis of the processes and infrastructure.

The ever-increasing demands placed on modern plants in terms of environmental, economic and (product) quality aspects can be met in the future by either continuous or batch heat treatment plants, the potential of which is far from exhausted. It does not matter, whether the potential is sought in a new plant or in the modernisation of an existing plant. An optimum solution can be found depending on the possibilities of the individual customer and adapted to his specific technical and economic requirements.

References

[1] Gula, G.; Fliess, M.; Wuppermann, C.: Potentiale zur Dekarbonisierung von Haubenglühanla-gen und aktuelle Entwicklungen, conf. proc., 4th Aachener Ofenbau- und Thermprocess Kolloquium;17. Oct. 2023, pp. 43-52.

[2] König, E.: Allan, M.: Roller Hearth Heat Treatment at the Cutting Edge of Technology; conf. proc., AISTech 2023, Dec. 2023.

The authors of the article are Dr. Gökhan Gula, Erik König and Malte Fliess, Tenova LOI Thermprocess. The terms “ecoBAF®”, “eBAF®” and “HPH®” are registered trademarks of LOI Thermprocess GmbH.

wire 2024, hall 10 booth A 59

LOI Thermprocess GmbH

Schifferstrasse 80

47059 Duisburg/Germany

Contact person is Eva Meyer

Tel.: +49 203 80398-880

eva.meyer@tenova.com

www.loi.tenova.com