26/03/2021 – Changing of wire material for forming

“Fine” technologies brighten forming industry

Asahi Sunac Corporation in Japan has continuously developed various advanced technologies for “forging machine and tooling” since 1959 (formerly as Asahi Okuma Industrial Company Ltd.).

Three featured “Fine” functions embody the net shaping in the forming products:

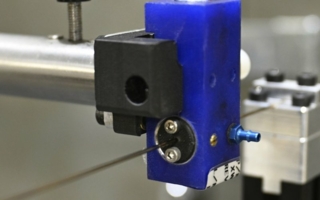

– “Fine” feed system (grip-and-pass the wire for high accuracy feeds that contribute to a high-precision forging performance),

– “Fine” cutoff system with a crank-driven cam mechanism (a precise high-speed cutoff mechanism produces beautifully straight, angular cutoff faces that significantly reduce variations in cutoff weights), and

– “Fine” slide system (a precise ram slide adjustment system reduces clearances between ram and slide surfaces, which results in improved blank concentricity.)

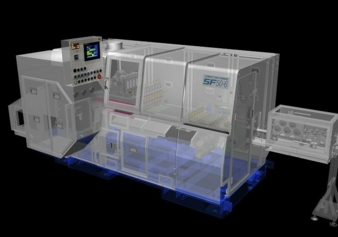

Especially the “SF50” with 6 and 7 station part formers becomes much popular due to the recent changes in market needs caused by an increasing demand for electronic parts related to the rapid rise of environmentally compliant hybrid and electric cars, as well as a progress in downsizing and form-complexity of parts according to the unit size reduction and compactness.

Changing of wire material for forming also corresponds the recent market needs. A cold/warm combined former enables the forming of products with hard, difficult-to-process materials such as stainless steel, etc.

More details and latest developments such as 2 station conventional headers and the latest model of SQ series cold headers as a new standard can be found on the company´s website.

The author is Yoichi Ito, Asahi Sunac Corporation.

Asahi Sunac Corporation

5050, Asahimae-Cho,

Owariasahi City, Aichi Pref. 488-8688/Japan

Tel.: +81561-52-0718

sunac_f@sunac.co.jp

www.sunac.co.jp/en/forging/index.html