04/03/2021 – Combination of finger benders, rotary positioning grippers and a servo transfer

Faster wire processing

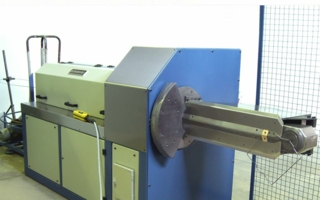

Schmale Maschinenbau GmbH presented its first, purely servo-electric wire bending machine of the type “X2000NC” back in 2012. The current generation of the machine is an evolutionary further development that sets new standards.

The modular structure and the variable equipment with a wide variety of units have been the trademark of the “X2000NC” from the start. With bending slides, punching presses, swaging presses and many other process units, all required cold forming processes could be operated on this machine. In addition, this type of system has always been fast thanks to the linear transfer that serves various forming stations at the same time.

Cam control instead of a step chain

In addition, the machine builders from Germany control their units by cam control via a virtual master axis and not by step chain programming. In this way, the processing steps can be blended with one another in terms of timing which leads to a further time advantage in processing.

Disadvantages of the system concept were the longer set-up times when changing items and the more expensive tools for the bending slides.

Advantages of finger bending and slide bending

The new machine concept now combines the advantages of finger bending and slide bending. Thanks to the now introduced combination of finger benders and rotary positioning grippers – instead of bending slides, the X2000NC achieves even faster cycle times for 3D bending operations. At the same time, however, the fact remains that several forming stations are operated simultaneously via the servo transfer.

For comparison: A conventional CNC wire bending machine with step chain programming produces 6-8 pieces of an 8mm wire bending article, each with 6 bends per minute.

The X2000NC creates up to 40 parts per minute and can also carry out further forming operations with no loss of speed. This means that the system is up to 8 times faster than its competitors on the market.

Short set-up times when changing items

The set-up times are extremely short, typical for the use of finger benders, and the tools are inexpensive. The exchange of a tool is done in approx. 2 minutes per station. Loading another, preprogrammed item via the touch panel only takes seconds. The axes move to the positions specified by the program. The production of this new item can be started within a few minutes already.

With the evolutionary further development of the X2000NC, the machine builders from the Germany have repositioned themselves and brought a very efficient and future-oriented generation of machines into the market.

Schmale has given this latest development its own special page with several videos on the company's homepage. Here the system can also be viewed in operation at top speed. www.schmale-gmbh.de/maschinen/x2000nc-mit-fingerbiegetechnik.html

Schmale Maschinenbau GmbH

Altenaer Strasse 95, 58762 Altena/Germany

Contact person is Jörg Kiesow

Tel.: +49 2352 54864-17

joerg.kiesow@schmale-gmbh.de

www.schmale-gmbh.de