10/11/2023 – Double twist stranding machines from Niehoff

Efficient stranding of larger power cables

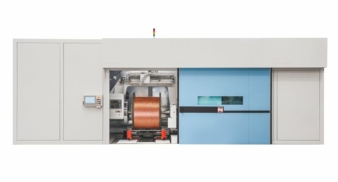

Maschinenfabrik Niehoff has been developing and building rotating machines for the cable industry for around 60 years, including the double twist bunching and stranding machines of the “D series”. This series now consists of eight different sized models designed for conductor cross-sections from 0.013mm² to 500mm². In recent years, the double twist stranding machines types “D 1252”, “D 1602” and “D 2002” were added*.

These three machines enable cable manufacturers to produce cables with larger dimensions, which are more and more required with the worldwide growing demand for electrical energy. The machines are designed to strand insulated wires and to strand and compact conductor constructions for power cables, flexible control, connection and motor cables as well as steel wires.

Characteristics

The “D 2002” is the largest model of the “D series”. In combination with an external rotating pay-off type “PTD 1000” it is able to strand up to 61 conductors together. The machine accepts spools with a flange diameter of 2m and a weight of up to 12t. The machine is designed for processing wires with a diameter of 1.5mm to 4.8mm into strands with a cross-section of 16mm² to 400mm² (Cu) or 500mm² (Al). The lay length is continuously adjustable from 50mm to 500mm, the maximum number of twists is 1000twists/min, the production speed is up to 150m/min. The strands can be compacted, whereby a degree of compaction of up to 13% is possible.

The “D 1252” model was the first machine of this series and brought to operational maturity in 2018. It is a further development of the “D 1251” but more adapted to specific applications. While both machines can strand conductors with a seven wire construction, for example 7mm x 3.05mm; the “D 1252” can also produce conductor constructions consisting of up to 19 wires. The “D 1602” model is specifically designed for conductors of this kind.

Energy-saving design and optimum conductor path

Like all machines of the “D series”, the three new models are characterized by the energy-saving one-bow design, which has proven itself in practice. The equipment also includes an energy-saving rotor drive of the energy efficiency class IE3 and a thermostat-controlled fan drive in the soundproof cabin which works depending on the temperature within the cabin.

During the design of the machines, attention was paid to optimising the conductor path. Gentle treatment is achieved, among other things, by the fact that all pulleys and capstans have large diameters. From the second deflection pulley to the haul-off capstan the conductor path is straight, which also contributes to a high conductor quality. The conductor can be compacted via a driven rotating compacting die with die lubrication.

Perfectly wound spools

The automatic laying system (NBAT) with flange detection system allows spools to be wound perfectly. Therefore, even at high speeds, the wound conductors can be paid off for further processing free of loops and without damage.

Easy operation and simplified maintenance

In the design of the machines also ergonomic criteria were taken into account: All three machines have a working height of 1,300mm, which simplifies the operator's work. The machines are operated via the Niehoff Machine Interface (NMI), a network-compatible HMI interface with colour touch screen. The screen displays notes and instructions, stored recipes, system status messages and other information in the operator's language. Wireless telemetry for all signals including encoders and the absence of slip rings increase production reliability and simplify maintenance.

Industry 4.0 and “myNiehoff”

The machines monitor the quality of the stranding process, for example the temperature of the rotor bearings and the vibration of the rotor. Machine and process data can be recorded, documented and evaluated via the “myNiehoff” web app according to Industry 4.0. Users of these machines can thus prove the product quality to their clients in writing.

* The type designations indicate the maximum spool size for which the machines are designed.

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach/Germany

Tel.: +49 9122 977-0

info@niehoff.de

www.niehoff.de