30/11/2023 – “PCD Mant” wire dies

Drawing copper plated welding wire

From three production sites in the heart of Europe (Germany, Italy, and Czech Republic) the Redies company delivers wire dies with mono-, and polycrystalline diamond as well as Tungsten carbide cores.

Furthermore, repolishing services and a range of materials, auxiliaries and machines for customers’ own die shops are part of their portfolio. The fraction of wire dies with polycrystalline diamond – PCD for short – cores made with Redies’ own brand “PCD Mant” has grown over the past 20 years. Today, almost all customers of PCD dies want to get this product.

The product line “Mant” is a complete system of PCD cylinders up to 30mm for all drawing applications: round wire, tubing, profiles, sliders, bunching, and special tools made according to customer’s specifications. The 5/2019 edition of DRAHT magazine featured an editorial about the self-supporting “PCD Mant MSD 06 001”. Their capabilities in drawing fine copper wire as well as the ability to substitute monocrystalline diamond dies from diameters 0.15mm and larger was highlighted.

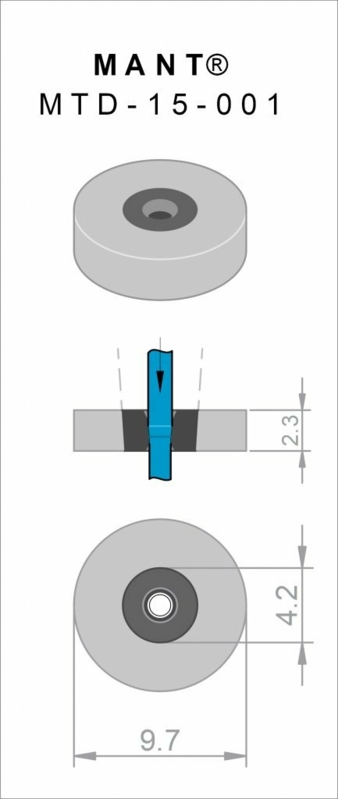

Likewise, in the field of steel wire drawing, especially copper-plated welding wire, “PCD Mant” is on the rise and gradually replaces tungsten carbide dies. Automated MAG welding of low carbon steels and automated MIG welding of Aluminum are present all across the industry in construction, automotive, fabrication of machinery and tanks, to name some examples. To be more exact, it is the “PCD blank Mant MTD 15 001” that has shown to be fit for the job.

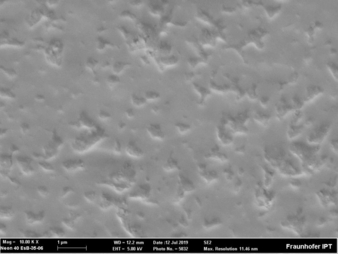

The “PCD blank Mant MTD 15 001” is suitable for drawing diameters 0.60mm to 2.00mm. It is made from fine-grain globular diamond powder which is sintered into a cylindrical Cobalt capsule and into a Tungsten carbide ring in a high-temperature, high-pressure process. To make a complete die, the core gets a stainless steel casing before being laser drilled and getting its finish with ultrasound tools. An example of the polished inner die surface can be seen in the following SEM image.

Three features make “Mant MTD 15 001” stand out

1) Choice of, and control over the source materials are essential for the resulting quality of the PCD blank. Only diamond powder with globular morphology and a very sharp grain size distribution is used. With it, a high degree of internal bridging can be achieved, and thus, a longer service life of the die. The choice of 1µm grain size was made to enable the customer to draw an excellent, shiny surface quality throughout the complete use cycle. Even the 4µm to 5µm copper layer on copper plated welding wires remains intact.

2) The aforementioned method of PCD fabrication ensures that the PCD does not wear loose from its TC ring; which in turn avoids wire breaks and subsequent down times of production lines.

3) In addition, Redies uses a conductive sintering process when casing their dies. This ensures an optimal bond between the core and sinter metal. Not only does this make a monolithic drawing tool, it also gives optimal heat transfer during the drawing process.

As of today, more than a dozen producers of welding wire, some of them in multiple production sites, are content in using “Mant MTD 15 001”.

More info at: mant.com/en/productinformation

Redies Deutschland GmbH

Metzgerstrasse 1, 52070 Aachen/Germany

Contact person is Ferdinand Kießling

Tel.: +49 241 504-222

info.de@redies.com

www.redies.com