16/09/2024 – Wire drawing / braiding

Cutting-edge wire and cable manufacturing equipment

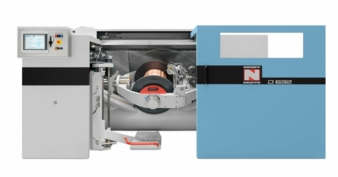

Maschinenfabrik Niehoff and its Chinese subsidiary Niehoff Machinery Changzhou (NMC) Co., Ltd. will display at the “wire China 2024” a “MMH 121 + RM 201” type multiwire drawing line, a “D 632” type double twist bunching machine with an “ARH 630” type pay-off, and a “BMV 24” type vertical braiding machine.

A future-pointing multiwire drawing technology

NMC builds among others MMH type multiwire drawing lines under Niehoff license for the Chinese market. These lines consist of components built and supplied by the Niehoff headquarters in Germany and components built by NMC. The mechanics of the MMH drawing machine belong to the first group, while the annealer, the switch cabinet and the spooling system are made by NMC. All components are assembled at NMC, where also the test runs are carried out. Only after succeeding the test runs, a line is delivered to the customer where NMC technicians are responsible for the installation and the startup.

The main advantages of the MMH 121 + RM 201 type multiwire drawing line on display are a compact design that allows space saving use of the production area, a high productivity, and a low wire break rate. The RM 201 type resistance annealer works with the field-proven 2/3 zone annealing which can be selected with or without wire reheating. The results are an optimum wire drying and an economical use of energy for bigger wire sizes.

The wires drawn on this drawing line feature over their entire length very homogeneous and closely tolerated properties. Such wires can be processed into multiwire bundles with excellent specifications and are ideally suited for final applications or downstream processing into high-quality strands or braids.

Technical data MMH 121

max. production speed: 35m/s

wire inlet diameter: 2.00mm or 1.80mm*

wire finished diameter: 0.16mm ... 0.55mm

max. number of wires: 24

*Cu hard

High quality strands for demanding applications

The D 632 type double twist bunching machine built by NMC under Niehoff license is characterized by high productivity and delivers high-quality products on perfectly filled spools. The single-bow design in combination with the energy-saving bow Eco-Bow installed in this machine ensures significant energy savings and thus significant energy cost savings compared to conventional bunching machines. Further features are an electric lay-length adjustment (changing lay-length without changing gears) and constant tension control of the strands from empty to full spool. As the D 632 produces bunches with very tight tolerances only the minimally required copper cross section is generated. This results in considerable material and operational costs savings. Due to the adjustable and controlled wire tension – regardless of the spool filling – and the integrated opto-electronic NBAT (NIEHOFF Bunching Automatic Traverse) system the spools are filled with a perfect winding pattern. As a concequence, the bunches can be payed-off tangle-free even at extremely high pay-off speeds.

Because of the precise mode of operation and the automatically working NBAT system one operator can supervise the operation of more machines at the same time. The result are substantial labour cost savings. The D 632 buncher is ideally suited for processing fine wires made from copper alloys such as CuSn0.3 into strands for automotive cables. Using the patented Stretch Forming and Straightening Technology, the D 632 avoids the crowning and spiraling effect typical for wires made from certain copper alloys.

Technical data: D 632

max. production speed: 300m/min

strand cross section*: 0.09mm² … 6.00mm²

lay length (steplessly variable): 6mm … 100mm

max. number of twists: 7,000twists/min

* Cu soft

Precision braiding with high efficiency and versatile application possibilities

The BMV 24 type vertical lever-arm rotary braiding machine equipped with 24 bobbin carriers features several main advantages such as an infinitely adjustable electronic control of line speed and braiding pitch as well as an automatic central lubrication system. Multiple monitoring systems enable unattended operation over longer periods of time and without frequent operator intervention.

BMV type braiders can be equipped with three patented systems, which ensure additional advantages. The braiding speed of a BMV 24 type model can automatically be accelerated from 110 rpm to a maximum value of 130 rpm, while a BMV 16, the 16 spool carrier version, even can accelerate the speed from 175 rpm to 200 rpm. The result is a 10% higher braiding performance. In the same time the frequency of the lubrication intervals is reduced depending on the slideway temperature. Thus, less lubricant is used and less oil contamination occurs on the braids.

With the help of Niehoff’s Wire Tension Control System, all braiding wires – from full to empty braiding bobbin – can be applied to the product to be braided under uniform tension. The result is a faultless shielding. Niehoff’s Coverage Control System ensures a constant braiding coverage ratio at the set value. Since only the absolutely necessary amount of braiding wire is applied, up to 10% braiding material savings can be achieved.

The BMV type braiders can be applied for a wide application range. They are designed for processing bare or plated round or flat wires made from copper, aluminum or stainless steel, and also artificial yarn and fibers. The braiders can be used to manufacture cable screenings, copper braids, hollow braids, stranded braids, textile braids and steel wire braids with different braid patterns.

Technical data BMV 24

oss section: 0.02mm² ... 0.56mm² *

max. braiding pitch: 6mm … 180mm

central passage: 50mm

* Cu soft

wire China 2024, booth E1 B51

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach, Germany

Contact person is Norbert Meyer

Tel.: +49 9122 977-0

info@niehoff.de

www.niehoff.de

Niehoff Machinery Changzhou Co., Ltd.

Shanghai Sales Branch

Room 2302, Hong Kong Plaza,

283 Huai Hai Zhong Road

Shanghai 200021, P.R. China,

Contact person is Jacky Chen

Tel.: +86 21 61202800

info@niehoff.cn