11/04/2024 – Cable manufacturing / winding

Customized ring winding systems

In addition to the design and implementation of overall systems for a variety of processes in the wire and cable industry, Kurre Systems is particularly well known for its extensive portfolio in the field of winding technology.

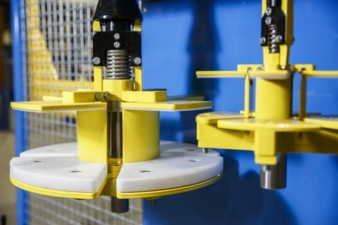

Ring winding systems play a critical role here. In particular, the smooth functioning of the reel coiler or the ring coiler body is crucial for perfectly wound rings. Kurre Systems also excels exceptionally well with this rather inconspicuous feature thanks to its "Customized Engineering" slogan: "Our reel is truly personalized in every respect," explains sales representative Marco Kreuzkam. "The product or the winding parameters requested by the customer determine the dimensions," continues Kreuzkam. "But the real highlight are our adapters," reports Kreuzkam, "This makes it possible to precisely increase the most important parameters such as winding width, core diameter and therefore the bending radius. This allows one reel to be used cost-effectively for winding several products." "Kurre Systems now has a wide range of reels that have already been converted and are reliably used to wind copper cables, rubber hoses and wire ropes, among other things.

The mode of operation is also well thought out: The reel is initially connected manually or automatically. After the winding process, the operator activates a pusher located in the center of the reel – the holding plates immediately fall outwards and the ring can be easily removed. Further processes such as order picking can be connected directly. The reel has a solid design and is purposely constructed for a long service life.

Visitors can see the quality and functionality for themselves at this year's “wire” in Düsseldorf. Here, visitors can expect a lot more information about the construction of special machines and the adaptability of systems and machines.

wire 2024, hall 10 booth C 18

Kurre Spezialmaschinenbau GmbH

Industriestrasse 5, 26683 Saterland, Germany

Contact person is Thorsten Wilde

Tel.: +49 4498 9250-120

thorsten.wilde@kurre-systems.de

www.kurre-systems.de