21/11/2024 – Strong, precise, and indestructible: CSS Belts

Conveyor technology for extreme conditions

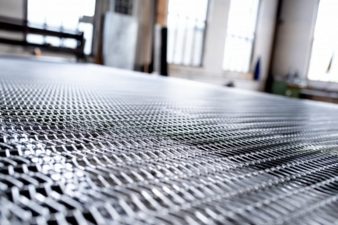

Whether it’s heavy loads, extreme heat, freezing cold, or corrosive acids – “CSS Belts” conveyor belts hold up. The meshes, fabrics, and spiral conveyor belts excel wherever the toughest demands are placed.

With the perfect mix of material strength and the right alloy, CSS Draht Schmidt from Lahnstein/Germany create the ideal conditions for durability and process reliability.

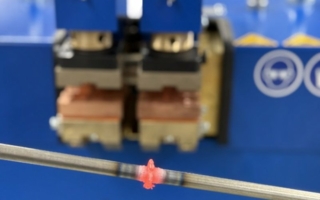

Despite several automated production processes, the company still heavily relies on skilled craftsmanship where precision is required – whether in assembly, confectioning, welding, or bending. Almost everything CSS produce is project-based and tailored to their customers' specific requirements. This flexibility makes them a reliable partner, especially when it comes to custom designs.

Materials and manufacturing techniques

For the production of their wire products, they use a wide range of materials, each selected to meet the specific demands of the application. From corrosion-resistant stainless steel alloys to high-strength wire ropes, CSS develop solutions designed to withstand extreme mechanical stresses. In the conveyor belt industry, in particular, they use a variety of wire types to meet the diverse requirements of different applications.

The manufacturing processes include high-precision braiding, weaving, and manual assembly of spiral belts, ensuring their products are perfectly tailored to customers’ needs. These technologies guarantee a consistent quality, which is indispensable in sensitive industries like food production.

CSS Draht Schmidt GmbH

C.-S.-Schmidt-Strasse 9

56112 Lahnstein/Germany

Contact person is Stefan Quast

Tel.: +49 2621 9694-0

stefan.quast@css-belts.de

www.css-draht-schmidt.de