08/04/2024 – Wire processing / straightening

Components for good

Electromobility is seen as a key technology for changing the current transport situation in the long term. The current focus is on the straightening process for process materials used to manufacture busbars and connection systems for the transmission of electrical energy.

The reduction of climate gas emissions is a politically defined objective that directly results in the motivation to turn away from the combustion engine and towards alternative drive technologies. The electric motor, with its simple design compared to the combustion engine, plays a central role. Assuming the availability of sustainably produced and inexpensive electricity in sufficient quantities, the concept is considered viable and is widely accepted. With this in the background, many developments relating to electromobility have emerged from the laboratories and found their way into mass production.

The acceptance of the global market is diverse, as there are many influencing factors, different conditions and diverse feelings. Regardless of this, the goal of decarbonising mobility is changing entire industries.

The effective production of electric motors means new processes, challenges and the need to work with new materials for many established manufacturers. The situation is no less complex when it comes to energy generation and supply. The green synthesis of hydrogen, the development and expansion of the infrastructure for its distribution as well as that for the distribution of electrical energy and battery cell production are all on the agenda among others.

Each of these focal points has its own tasks and problems that need to be mastered and solved. “Witels-Albert GmbH is in demand in this context, as our understanding of processes and the resulting products support and drive forward many producers. We are proud of our products and experiences in the processing of electrical sheets and high-pressure tubes, the manufacture coated profile wires, busbars, windings, hairpins and axial flux coils, which are assigned to the processes of guiding, straightening and feeding”, says Managing Director, Marcus Paech.

Straightening

The current focus is on the straightening process for process materials used to manufacture busbars and connection systems for the transmission of electrical energy. The connections must be robust and reliable and they must be able to be quickly and efficiently inserted into the respective structure, often in the tightest of spaces. High voltages, thermal conductivity, cooling and other issues are challenges for developers and manufacturers worldwide. Inexpensive and efficient production equipment is required to manufacture the process material and the finished products.

A very good and constant curvature and/or process material straightness in the main axes of inertia of the cross section of the material is an indispensable criteria for the manufacturing and processing procedures. Against this background, the materials copper or aluminium, which are usually coated with “PA 12”, must be straightened gently in the planes of the main axes of inertia. For straightening process materials up to 55mm wide and 10mm thick, various newly developed models of straighteners are recommended.

The “BBS 7-60 PO -04” straightener is perfectly designed for flat straightening. The design uses identical chocks for the individually adjustable upper and lower cylindrical straightening rollers. The four lower chocks are each connected via two connecting elements to an upper chock, which is designed with an internal thread. These adjustable parts are positioned via an associated spindle with a hexagon socket. The three upper chocks do not require any connecting elements and each support one roller directly. All straightening rollers can be positioned in a defined and reproducible manner using mechanical position displays “PO”. The designs of all parts of a spindle mechanism are optimised with the aim of achieving maximum repeat accuracy when adjusting a straightening roller. In order to keep the overall mass of the “BBS 7-60 PO -04” straightener as low as possible, the majority of the individual parts are made of wear-resistant aluminium alloy. Through hardened rollers, fine thread positioning of all straightening rollers and the ability to maintain or change straightening rollers quickly and easily are features appreciated by operating personnel. A wider design of the straightener “RA 5-25 PO 02” is used for the elasto-plastic alternating deformation of the process material over the high edge or width. Like the flat straightener, the high edge straightener uses individually adjustable straightening rollers, which are arranged in two rows alternately offset and can be adjusted in a defined and reproducible manner. The groove geometry of the straightening rollers ensures tilt-free deformation in the relevant main axis of inertia of the process material.

Feeding

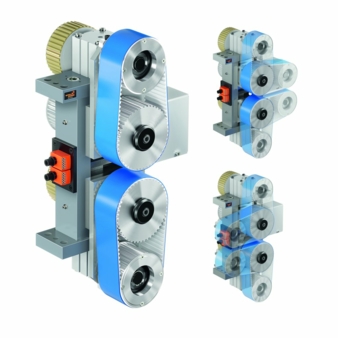

Feeding units with transport belts can be used to transport the process material relative to the straighteners with non-driven straightening rollers described above. They provide the transport force required for the peripheral transport process. Witels-Albert offers two series of feeding units with transport belts. As an alternative to transport rollers, they offer a higher coefficient of friction and lower pressure in contact with the process material. This ensures gentle process material transport and, for given values of contact pressure and torque, greater transport forces are achieved with transport belts than with transport rollers.

The models of the well-known “NAK” and “NAK Z” series differ in the way they clamp the process material and in their performance. All “NAK” models clamp a process material with a fixed edge. The “NAK 60 Z” and “NAK 160 Z” feeding units, on the other hand, use transport belts as tools that clamp the process material in the centre.

With the newly developed “NAL 160 Z” feeding unit, Witels-Albert is adding a third series to the existing series of feeding units with transport belts. The “NAL 160 Z” product closes the performance gap between the “NAK 60 Z” and “NAK 160 Z” feeding units. When supplied with a torque of 180Nm, the new development “NAL 160 Z” offers a maximum transport force of approx. 2.5kN. The unwinding length of the transport belts is more than 60% greater than that of the “NAK 60 Z” product. In addition, process materials up to a maximum width of 75mm can be reliably clamped and transported via force or friction fit. When it comes to transporting narrower process materials, Witels-Albert recommends a customer-adjustable positioning of the feeding unit, which supports the wear of the entire width of the transport belt and thus significantly increases the service life of the tools. Further features of the “NAL 160 Z” feeding unit are the defined and reproducible zero line or infeed height that can be set using “PO” mechanical position displays and the option of swivelling the support arms carrying the transport belts.

These features allow the customer a high degree of flexibility in terms of possible applications. Both centric and non-centric feeding of process materials in a wide thickness range are possible on a processing line. The swivelling support arms have a direct impact on the surface pressure between the tools of the “NAL 160 Z” feeding unit and the process material and allow perfect adaptation to the desired feed direction. Witels-Albert recommends the use of the “NAL 160 Z” product for the processing of coated or uncoated soft process materials as well as for high-strength wires and/or strips.

wire 2024, hall 9 booth E 39

Witels-Albert GmbH

Malteserstrasse 151-159

12277 Berlin/Germany

Contact person is Marcus Paech

Tel.: +49 30 72398811

paech@witels-albert.com

www.witels-albert.com