24/11/2023 – Broad range of braiding and spiralling machines

Braid and tape shielding of cables

Increasing cable shielding requirements in the automotive industry, data transmission and high-frequency cables are achieved through the pairing of braiding or spiralling and taping shields.

The tape can be applied in longitudinal or spiral orientation through concentric or eccentric applicators.

The driving forces include increased requirements on shielding parameters and return loss, reduced use of copper for weight savings, increased requirements for fire resistance and resistance to moisture etc.

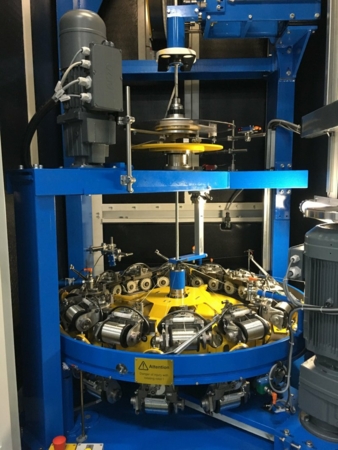

Spirka Schnellflechter GmbH (SSB) offers a broad range of braiding and spiralling machines and has developed a number of suitable tapers for most applications on SSB and Wardwell machines. In the past, the binding process was done separately from the wire shielding. SSB has combined the two processes to offer customers savings in:

– single reel handling

– floor space

– time and labour cost

– lead time

The following taping solutions are available from a single source:

1. “Longitudinal Tape Units” for all common materials for both vertical and horizontal braiding and spiralling processes accommodate tapes of widths up to 200mm and tape disc diameters of 400mm to 500mm. These tapers employ various brake systems depending on tape tension required.

2. “Concentric Tapers” are integrated in the braiding or spiralling machine for tape discs of diameters up to 500mm.

3. “Stand-alone concentric tapers” can be installed before or after the shielding process and are controlled from the main OP station.

4. “Stand-alone concentric taping units”, installed before or after the shielding process, can be configured with own controls, hold multiple tape discs up to 500 mm diameter and achieve operating speeds up to 1000rpm.

These taping options, for all common taping materials, can be effectively paired with SSB and Wardwell machines.

In addition to these taping options, Spirka Schnellflechter also offers copper taping machines for the taping of medium voltage cables.

Spirka Schnellflechter GmbH

Wilhelminenhofstrasse 76-77

12459 Berlin/Germany

Contact person is Thomas Uhlig

Tel.: +49 30 549918-41

tuhlig@spirka-schnellflechter.com

www.spirka-schnellflechter.com