01/11/2019

Avant-Garde welding machine

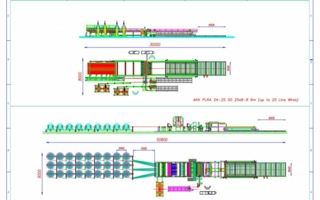

Eurobend's “PL AKK“ welding line sets new standards in mesh production, as eliminates all idle times and at least doubles productivity in comparison to conventional welding lines.

The production of all types of standard mesh is achieved instantly, without any adjustments. The machine concept allows automatic mesh spacing and dimensions changes. Wire feeding by a single coil replaces all line wire de-coiling stations, where the feeding concept of redundant line and cross wire de-coiling stations ensures continuous operation, without down times when one coil ends.

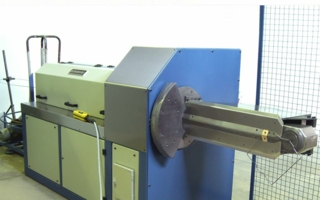

The patented “Automatic Wire Orientation System” (AWOS) allows the use of a high speed roller straightening module for line wire feeding up to 12mm. The unique AWOS system absorbs all wire straightening imperfections from the roller straightener and ensures perfectly flat mesh panels regardless of wire and straightening quality.

Also, the unique wire feeding system that allows diameter changes in a fraction of time in comparison with the conventional mesh welding lines, allows multiple diameter changes in one shift (or day) without wasting time and production. Ideal for “JIT”(Just in time) production and efficient product changeovers.

The flexibility offered by AKK welding lines eliminates the necessity for large stock of ready mesh as in conventional welding lines. The AKK machine can process up to 12mm coiled material, for the cross and line wires. The AKK Series are available in smaller machine versions, processing diameters up to 6mm, 8mm and 10mm coiled material. Capable of producing large and small batches-orders (or even one-off orders) consecutively without any downtimes.

The superiority of the PL AKK series is reflected by the fact that this machine became a popular welding machine in the wire welded mesh production market since it was introduced. More machines of this type are in operation in USA and Europe. Following the two previous installations of our mesh welding lines at Vimco Inc, located in Philadelphia, PA/USA, their third welding line, type PL AKK was their latest Eurobend installation of this machine type.

Eurobend GmbH offers innovative, sustainable solutions and a comprehensive range of automatic mesh welding machines, flexible automatic mesh welding lines for engineering and special mesh, spacer and bar supports welding machines, 3D fence panels and others.

Vimco Inc.

300 Hansen Access Rd

King of Prussia, PA 19406/USA

Tel.: +1 610 7680500

www.vimcoinc.com

Eurobend GmbH

Alexanderstrasse 1

90547 Nuremberg/Germany

Contact person is Harris Athanassopoulos

Tel.: +49 911 9498980

info@eurobend.comwww.eurobend.com