20/05/2019

40 years on the market for screw machines

The private Italian company TLM since 1979 has been manufacturing roll machines. Managing Director Pietro Sorli emphasises that a “more” of electronics has often proven to be unproductive.

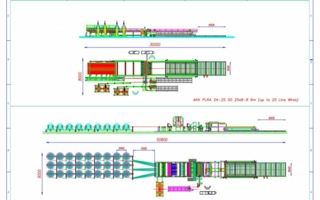

Tortona/Italy (TLM) – The mechanical adjustment is more flexible, easier to learn and foregrounds the importance of this type of construction, the manual skills and attention. There are useful electronic applications, such as sensors to check deformation. But the basic functions of the machines must remain mechanical. A special feature of his house are combined or multifunctional machines. The automotive industry is the most important market. If a part requires three operations, it is not economical to use three individual machines with the corresponding loading and unloading processes and washing of the parts, says Sorli.

A multifunctional machine can perform all operations and produce the finished part in a single operation. The costs for the system would be offset by these huge time savings. TLM develops new machine types in contact with its customers. The latter present a part to be produced and the company proposes a solution that allows all machining or coupling operations with washers or bushings to be carried out in a single step. TLM has developed special solutions for charging washers and loaders that carry bushes on the screw or for mechanical bolt alignment systems. A preliminary project presents all the solutions with an estimate of the machining times. From here it usually goes into the test and prototyping phase. The execution is disclosed when the sales contract is concluded. Over the next ten years, TLM intends to make the mechanical settings on the machines even more intuitive. Work should be made easier for the operator. TLM machines are durable, as shown by the many revisions they undergo over time. The basic construction – the machine head – is designed so that it can be reground. This grinding process is something that many manufacturers regard as useless. For TLM, however, it was essential, says Pietro Sorli.