19/03/2021 – Wire bending

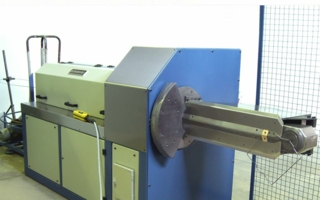

Two-dimensional bending machine “MTF66”

The Cometo “MTF66” two-dimensional bending machine with a chamfering system is suitable for processing material with a diameter from 0.8mm to 6.0mm and with wire chamfering from 2.0 to 6.0.

Thanks to the roller straightening system it is adaptable to the processing of rounds, squares, hexagons, and profiles with any other shape and it is also adaptable to straighten materials such as steel, copper alloys or aluminum without damaging the surface.

The “MTF66” bending machine is assembled on a electro-welded frame designed specifically to meet every need using wire straighteners of various sizes, three different types of feeders and three different types of cutting units.

The “SM12” chamfering unit performs a “V” incision on the straightened wire that is cut at the incision. The machine can chamfer on one end, or both ends, or not.

The unloading system of the machined pieces is available for a maximum length of 900mm or according to customer requests. The bending axis is managed by a brushless motor to ensure speed and precision.

Another advantage of the MTF machine is its extreme silence, a very important value to consider for operators who deal with this type of machines daily.

Cometo SRL has gained a leading role in the wire, cable, rod and tube industry for more than 35 years by being at the leading edge of technology. Cometo’s continuous cooperation with the most efficient and productive world leader manufacturers has made Cometo a reliable partner in the supply of high quality wire straightening machines, guides, cutting units and traverse units.

Cometo SRL

Via Cabella Lattuada 41

23841 Annone Brianza Lc/Italy

Contact person is Alessia Tocchetti

Tel.: +39 0341 263090

p.tocchetti@cometo.eu