27/09/2021 – Measuring and control technology

Special focus on Industry 4.0

Sikora’s booth at “Interwire 2021” will put the spotlight on innovative measuring, control, inspection, sorting and analysis systems. They contribute to the highest product quality, process optimisation and cost saving in the wire and cable, optical fibre and plastics industries.

“At Interwire, customers can experience a wide range of Sikora systems for wall thickness, eccentricity, diameter and ovality measurement. Depending on the application, we have several options available to meet customers’ needs”, says John Dognazzi, Managing Director at Sikora International Corp, and concludes, “We are looking forward to a successful Interwire show this year, and we are excited to discuss technology and projects with customers and friends in person again.”

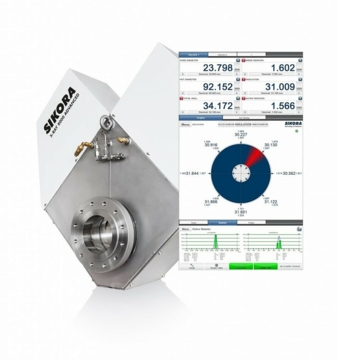

A highlight will be the “Centerview 8000“. The system is used in automotive and data cable extrusion lines to measure eccentricity, diameter and ovality of cable with a diameter from 0.25mm to 25mm, with a high single value precision. The operator immediately receives data about the cable dimensions that can be instantly used to control the extruder speed or haul-off speed and center the cross head. This ensures maximum quality, material savings and a repeatable production process.

Another popular Sikora system is the “X-Ray 8000 Advanced“ for CV lines. This device stands out with its quick and efficient measurement of the diameter, ovality, wall thickness and eccentricity during manufacturing of HV and EHV cables. The operator benefits from a fast centering of the cross head as each change of the centering screws is immediately registered and visualised. This results in achieving an optimum cable quality and process control.

When HV cables are being produced, the “Purity Scanner Advanced“ is a future-oriented solution for providing clean material into the production process. This device inspects the purity of XLPE pellets that are used for the cable insulation before they enter the extrusion process. The system combines X-ray technology with a dual or triple axis optical system and can detect impurities as small as 50 µm either on or inside the pellet. Contaminated pellets are automatically ejected from the pellet stream by means of compressed air.

Sikora is also looking forward to participating in the “Industry 4.0 Pavilion” organised by WAI where the company will explain how measuring and control technology contributes to the concept of autonomous manufacturing. Today’s cable production process is already characterised by an increasing level of automation. Sikora measuring devices continuously measure and transmit measuring values as well as information on the device status via Industry 4.0 interfaces. These interfaces, such as OPC UA, control information going to the plant control centre without the need for personnel support. There, the data is processed automatically for an immediate production control and process optimisation. This advanced approach leads to more efficient production.

Sikora International Corp.

Interwire 2021, booth 730

Tel.: +1 770 486 1233

www.sikora.net