07/05/2019

Rubber and silicone extruders on the path to 4.0

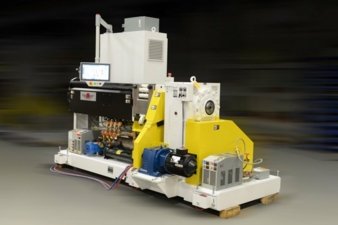

American Kuhne’s “Ultra R/S” extruders for rubber and silicone provide measurable improvements in process performance, serviceability, and longevity. The “Power Hinge” roller feed assembly opens with the push of a button providing total access for common service and maintenance.

On the path to 4.0, a recent innovation is the extension of the company’s “XC200 Navigator” controls system to its American Kuhne Ultra R/S extruders. It provides control for one or more extruders in simultaneous operation. The HMI is via a panel or optional swing-arm mounted screen map with integrated hard-wired Estop, Start, Stop, and Reset pushbuttons. It offers intuitive, visual navigation by touchscreen with easy to understand graphical displays of controls, status and alarms along with integrated machine documentation. The system enables operators to monitor and control functionality, including: closed loop barrel PID heat/cool control; clamp and die zone control; heater burn-out detection/alarm; high temperature alarm; melt pressure monitor with dual alarms; high pressure shutdown; soak timer/cold start interlock; hour meter; 7 day timer; extruder screw speed control (start/stop, speed display, amp display); alarm history, 365 days; security access manager; recipe manager; trending of any parameters that are monitored and controlled; integrated, real-time I/O diagnostic and remote diagnostics. These features are readily accessible even when remote via smartphone using the optional “Team Viewer” application.

American Kuhne

Interwire 2019, booth 1357

Tel.: +1 404 386-6830