20/10/2020 – wire 2020 update

Roteq Machinery cancels participation

Roteq Machinery has taken the decision to cancel participation at “wire” 2020 due to the ongoing travel and risks due to the pandemic.

Roteq personnel are available by telephone or video conference for discussions in lieu of the trade show. Contact Roteq to discuss its capabilities and developments in stranding technology for copper and aluminum conductors with single-twist, double-twist, concentric, roll forming and SIW conductors. Double twist shielding for instrumentation cable. Drum twisters, planetary, single and double twist, and S/Z for cabling. Group twinner for LAN cable. Strip armoring 50mm/125mm including in-line cabling and packaging. Auxiliary equipment including pay-offs, take-ups, taping, binders, yarn servers, capstans, and caterpullers in custom engineered solutions for unique product challenges.

Technologies that Roteq offers include:

– High speed precision planetary cabling utilizing driven rotating pay-offs and take-up with no slip rings or brushes.

– Roteq’s next generation V16 strip armouring machine featuring improvements in operator experience and reduced maintenance.

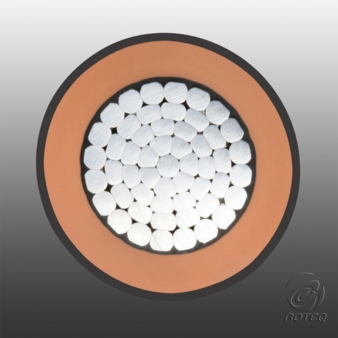

– Roteq’s industry leading roll forming of compact aluminum conductors in-line with the stranding process, allowing a range of conductors to be stranded from one round input wire size (SIW). This reduces work-in-process inventory and improves productivity.

– S/Z cabling technology for high speed cabling of control and instrumentation, fire alarm and similar cables which provides the ability to cable from stems and output onto any size reel.

– Optical Ffber stranding using planetary, rigid cage, and drum twisters for ribbon, loose tube, and tight buffer cables.

Roteq Machinery Inc. develops and manufactures rotating equipment for wire and cable, umbilical, and hose industries. Each project starts with understanding the product and process requirements to define machine characteristics and culminates with a machine design specific to the application. The portfolio of completed projects span the full range of rotating equipment including armouring, stranding, cabling, taping, and includes auxiliary equipment for complete production lines for copper, aluminum and optical fiber. Roteq provides equipment, spare parts, and field service from its facility near Toronto, Canada.

Roteq Machinery Inc.

wire 2020, no participation in this year

Tel.: +1 905 660-8800

www.roteqmachinery.com