27/03/2019

How to solve dust issues

More and more, the wire drawing industry is concerned about dust in the production. With this in mind, French company Condat will be presenting a paper and holding a training course on dust reduction during the Interwire show.

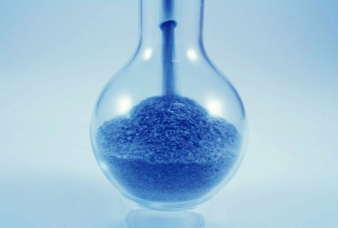

Thanks to its 160 years of expertise, Condat will give technical guidelines for the selection and use of the most suitable dry drawing lubricants. The objectives being to significantly reduce the amount of dust generated in the workshop, improving productivity whilst also reducing total wire drawing costs. Overall, the reduction of dust particles is central to lowering the exposure risk of operators and explosion hazards. It also reduces related maintenance costs and downtime.

At the exhibition, Condat will introduce its latest products dedicated to extra high tensile steel cord wire production including

- A non-reactive surface coating booster for borax baths, and

- High performance sodium soap based dry drawing lubricants, including borax free products.

The latter have been developed for high speed drawing with low lubricant consumption and extended die life. Condat will also present its new generation of lubricants for stainless steel and cold heading wire, all free from short and medium chain length chlorinated paraffins: short chain lengths are banned and medium chain lengths are subject to EPA regulations.

Condat S.A.

Interwire 2019, booth 1351

Tel.: +33 4 78073838