26/04/2022 – Eco-designed lubricants

How to manage lubricant residuals on drawn wire

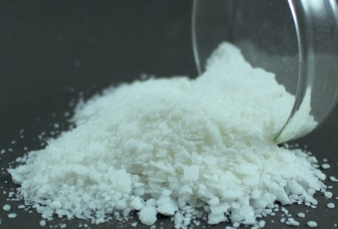

Condat’s lubricants range is recognized as a world reference in the wire drawing processes and offers the widest choice of soaps, surface treatment products, neat and soluble oils.

Because each wire drawing plant is different, Condat experts develop lubricants answering customers specific needs and guide them to the best lubrication strategy. Condat provides support towards a responsible performance. For wire drawing, it offers 40 eco-designed lubricants rated through its self-scoring “Lubriscore”. Particular attention is paid to the raw materials used in formulas, which limit as much as possible the use of hazardous ones.

Besides providing customers eco-designed lubricants, the company is keen on solving their day to day issues. Thanks to its long expertise in the wire industry, Condat experts give technical guidelines for the selection and use of the most suitable dry drawing lubricants. Many of them can also be addressed by Condat team, such as reducing total wiredrawing costs, reducing the amount of dust generated in your workshop, improving your productivity or getting the most out of your precoatings, and so much more…

To illustrate, during upcoming “Wire Expo” show in Dallas, Texas, USA, Condat will hold a conference on “how to manage lubricant residuals on drawn wire”. Indeed excessive residue can cause problems to process and is also an indication of lubricant overconsumption; while too little residue can lead to premature die wear. The quantity of residue can be adjusted by varying a number of parameters. Such as type of dry lubricant used during wire drawing operation: fat type, grain size distribution, softening point, type of filler; even die type and profile: angle and bearing can play a role on residuals. To know more, follow up this conference or meet Condat experts at booth 513.

Condat SA

Wire Expo 2022, booth 513

Tel.: +33 4 78073838

www.condatcorp.com