17/10/2022 – Condat expanding with a new plant in China

Eco-designed lubricants with awesome service

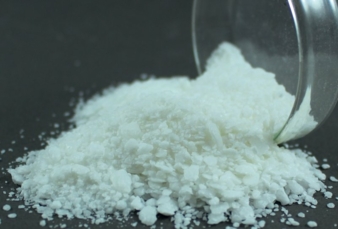

Condat’s lubricants range is recognised as a world reference in the wire drawing industry and offers the widest choice of soaps, surface treatment products, neat and soluble oils.

Because each wire drawing plant is different, Condat experts develop lubricants answering specific needs and guide their customers to the best lubrication strategy. Condat provides support towards a responsible performance. For wire drawing, it offers 40 eco-designed lubricants rated through its self-scoring “Lubriscore”. Particular attention is paid to the raw materials used in formulas, which limit as much as possible the use of hazardous ones.

Besides providing customer eco-designed lubricants, the company is keen on solving day to day issues. Thanks to its long expertise in the wire industry, Condat’s experts give technical guidelines for the selection and use of the most suitable dry drawing lubricants. The team can cover many topics, such as reducing the overall cost of wire drawing, reducing dust in a workshop, improving productivity or making the best use of pre-coating and much more ...

To illustrate, Condat can help to manage lubricant residuals on drawn wire. Indeed excessive residue can cause problems in process and is also an indication of lubricant overconsumption; while too little residue can lead to premature die wear. The quantity of residue can be adjusted by varying a number of parameters. Such as type of dry lubricant used during the wire drawing operation: fat type, grain size distribution, softening point, type of filler; even die type and profile: angle and bearing can play a role on residuals. This is where the Experts can help customers to adapt these parameters depending on process in order to increase productivity.

As an industrial group, Condat has invested in state of the art facilities to produce consistently high standard lubricants on 4 continents. Already present in China with a local production unit in Shanghai, the company is now expanding with a new plant settled in Qingdao, starting by the end of this year.

Indeed Condat has made it a priority to be located near to its customers, both geographically and culturally with dedicated experts. The new plant will allow Condat to increase its production capacity by using the latest modern equipment with associated quality management. Also, with local storage facilities, Condat promptly delivers products with a consistent quality to any location, enabling its customers to reduce their environmental and transportation impact.

Condat

wire China 2022, booth 13 H 10

Tel.: +33 4 78073711

www.condat.fr