13/05/2021 – Semi-conductive or permanent dissipative PVC compounds

Delta Tecnic improve safety in electrically charged environments

Delta Tecnic, a specialized company in the production and commercialization of colour concentrates and raw materials for plastics and cables is committed to the development of PVC compounds with permanent conductivity to reduce the hazard potential in environments with electrostatic charge, to avoid unwanted electrostatic charges, explosions or fire.

Thanks to its formulations, Delta Tecnic's conductive compounds meet the requirements of European ATEX regulations, which ensure safety in areas classified as explosive atmospheres. Such environments are generated in industries that handle highly dangerous products such as fuels, hydrocarbons, fine-grained dusts or explosives, as well as in the petrochemical, plastic transformers, hospital and electronic sectors.

Uncontrolled electrostatic discharges (ESD) are created when a charged object, often plastic, is in contact with another material. The easiest way to prevent the generation of static electricity is to replace the insulating plastic with a semi-conductive or dissipative plastic. Delta Tecnic's conductive PVC compounds offer advantages over metallic coatings, as they are lighter and easier to handle and simplify the part manufacturing process in many instances.

Stability, consistency and flexibility

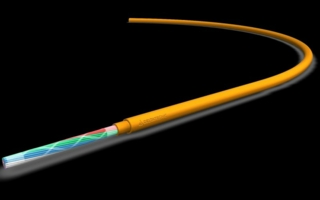

The conductive/dissipative properties of Delta Tecnic PVC compounds are permanent over time and maintain stable conductivity values, even with varying atmospheric humidity. This product class is designed to be consistent even in thin extrusions and is available for a wide range of applications ranging from pipes, tubes and packaging to geomembranes and cable insulation. The conductive compounds are made from highly structured carbon blacks, together with new additives such as graphene or carbon nanotubes. The mixture of these components allows the creation of flexible and semi-rigid PVCs, especially for the cable, hose and pipe industry, as well as for technical areas of construction.

Delta Tecnic S.A.

Tel.: +34 93 8674284