21/10/2020

Cable manufacturers needs film, foils or tapes

Gurfil Foil-Film-Tape+Machinery A.S. told us a new hall and stand number at “wire” 2020. “Hall 13 booth C 64”, so Svetlana Dogusoy, export manager.

Gurfil serves their customers throughout the world with Foil, Film and Tape products together with Machinery, including on-site support and after-sales technical service. Up to today they expanded their product range into three main groups with more than 100 products. These products are:

Foil, Film and Tape Group: ALU/PET, ALU/Copoly, CU/PET laminates, Polyester film (Mylar, PET film), Mica tape, PP Identification tape, Polyester non-woven tape, Copper foil, Fiberglass tape, PP foam tape, Kraft paper, Crepe paper, Semi-conductive tape, Waterblocking tape, Fiberglass yarn, Ripcord yarn, Waterblocking soft Yarn etc.

Wire Group: Aluminum Alloy Wire (0.12mm, 0.16mm), CCA and CCS, Skin-Foam-Skin 3 Layer Physical Foamed Conductors.

Machinery Group– At the moment they offer following machines together with commissioning:

– High Speed Vertical Braiding Machines (16 and 24 carrier)

– High Speed Horizontal Braiding Machine (24, 32, 36 and 48 carrier)

– High Speed Mica Taping Machine (1,2,3 carrier, Pad and Spool head options)

– Winder lines

– Pay-Off and Take-Up

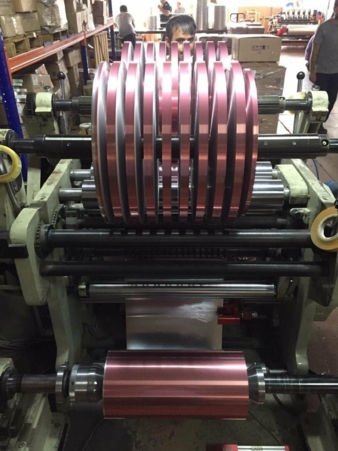

Their newly installed three spooling technology lines allowed them to increase significantly the production capacity meeting all necessary safety and quality requirements to the cable raw materials. Greater length of material is one of the advantages of spool winded Cable Raw Materials usage. A cable manufacturer can run its taping unit for a longer period of time without having a break, which means saving time on changing the bobbins and minimizing the cable waste. Also spool winded materials has a better and safer packaging way for transportation.

Gurfil Foil-Film-Tape+Machinery A.S.

wire 2020, hall 13 booth C 64

Tel.: +90 212 8868618

www.gurfil.com