15/03/2019

Bypass control system for extrusion of foamed insulations

In the production process of physically foamed data and high frequency cables the reduction of start-up scrap is the key point for production efficiency, cost saving measures and sustainability strategy.

Siebe Engineering together with Erocarb SA put a lot of effort into the development of an intelligent bypass control system that enables a line operator to start up a physically foamed cable in an ideal working point. In this way, the scrap length of a foamed cable can be reduced at each start-up almost by a factor of 10 which shows the huge potential of this bypass control system in terms of process optimisation and cost savings.

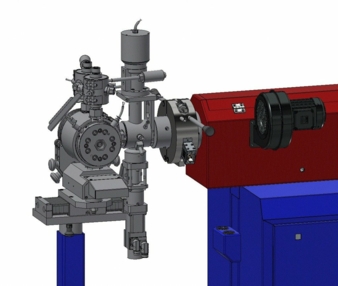

In general, the conception of the intelligent bypass control system is mainly based on a sophisticated mechanical device that is driven by an electric motor. With this technical approach every melt pressure value can be exactly adjusted within the extruder barrel. No polymer melt is pressed through the extrusion crosshead and so, at start-up of a product the extrusion process parameters are already in a steady state.

From the beginning on the bypass control system was designed as a stand-alone module that is equipped with its own CPU and a touch panel for the user interactions. This means that the described intelligent bypass control system can be easily integrated in every main control system of a cable production line. The “old” bypass has to be replaced, only. In case of Siebe cable production lines the retrofit can be carried out with integration into the main control system.

Siebe Engineering GmbH

Interwire 2019, booth 332

Tel.: +49 2683 30030