16/07/2020 – Automation of joining processes

Brazing rings for a higher degree of automation

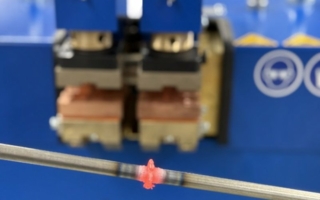

Brazing rings made of the high-temperature solder “Isa-Braze“ make higher degrees of automation possible and enable individual adjustment for customer requirements.

The solder family „Isa-Braze“ that includes the Isa-Braze 970, Isa-Braze 970 Si and Isa-Braze 980 (based on manganese) is used as a high-temperature solder and functional material by Isabellenhütte, the specialist for precision alloys. They are ideal for joining and coating all kinds of steel, nickel alloys and hard metals, as well as hard-to-join alloys such as chromium, molybdenum or tungsten.

Brazing rings of Isa-Braze are especially practical to handle when joining. One brazing ring can be put over the components to be joined and then positioned precisely where the soldering needs to be done. This is interesting e.g. for the soldering of hydraulic and magnetic valves or for the joining medium-conducting thin-walled pipes and flanges for which it’s very difficult to weld due to the low thickness.

The advantage of Isa-Braze is the purity of the material, because it is made from pure virgin metal. This results in the improved processing properties of the material – in contrast to soldering with recycled materials. The chemical and electrophysical properties are advantageous with respect to thermal conductivity, electrical conductivity, specific electrical resistance, thermal stress and temperature coefficient. Isa-Braze is very suitable for high-temperature soldering (> 900 °C, in vacuum conditions) because it does not require any flux. This creates very homogeneous and cleaner soldering points. In addition, no straightening is needed after soldering because the material is very low-tension. Isa-Braze can therefore be automated very well, which streamlines the joining process considerably.

“The automation aspect is often critical for customers,” says Michael Sting, Area Sales Manager at Isabellenhütte, “because a higher degree of automation means more efficiency.” The brazing rings can be adjusted for individual requirements. “We see ourselves as metallurgists primarily, who advise the customer about the properties and functionalities of the alloys,” explains Michael Sting. “For instance, we can change melting points using certain alloys to optimize the soldering properties. In addition, we function as a development partner to find solutions together for automating joining processes and e.g. for making meticulous geometries possible in very small tolerances.” In addition to individual solutions, brazing rings of Isa-Braze are also available as a standard product in bulk quantities. Further deliverable forms include wires and rods, as well as die-cut and bent parts, and flat wires and belts.