04/12/2025 – £250,000 boost Emergency Manufacturing Service

A major uptake

A desire for leaner inventories and quicker stock replenishment to meet fluctuations in demand has led to a major uptake in Alloy Wire International (AWI)’s Emergency Manufacturing Service (EMS).

The specialist in precision drawn round, flat, profile and wire rope has reported £250,000 of sales to companies involved in aerospace, energy and oil and gas over the last six months. Honed through nearly eighty years of industry experience, the EMS fast tracks a request in just five days, from receiving the order it goes through to its technical team, allocation of raw material and into production. The coordinated effort between sales, manufacturing and despatch delivers an essential lifeline to firms who need the material quickly to meet critical demand for end applications that deliver energy, save lives and fuels the innovation projects of the future.

“I believe the surge in enquiries for the Emergency Manufacturing Service reflects the volatility in the marketplace, with customers wanting things quicker and others worried about supply chain disruption,” explained Paul Chatterley, Sales Executive at Alloy Wire International. “Another big driver is also involvement in an increasing number of prototype products and trial quantities, especially in short batches.” He continued: “It has certainly been our busiest year yet for this service and we are looking to invest in making the process quicker. Even now, at five days, it is probably four times quicker than anything else industry can currently offer.”

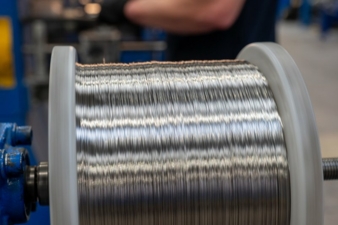

Alloy Wire International, which recently took on an additional 8,000sqft unit near its headquarters in the West Midlands, manufactures round, flat and profile wire in 62 Exotic alloys, such as Inconel, Monel, Hastelloy, Nimonic and Waspaloy. Today, the firm continues to supply 6,000 customers across 15 different market sectors and is set up perfectly to expand after completion of a £1m investment drive, with the installation of new wet drawing and single hole dry drawing machines.

International sales continue to grow and now account for more than 60% of the firm’s annual turnover, with its biggest international territory being the US, followed by France and Germany thanks to the hard work and contacts of Davidon Industries and Sopa Stahl.

Paul concluded: “The Emergency Manufacturing Service is one of the most powerful weapons in the AWI arsenal, but we’re continually looking at how we can make future improvements.

“This could include greater automation in order tracking and digital production scheduling, allowing customers to receive real-time progress updates.

“EMS has played a critical role in supporting the ventilator build during the pandemic, the development of next generation aircraft and in deep sea oil exploration and, I dare say, 2026 will bring a whole new set of critical applications.”