20.03.25 – A Design Choice for Longevity

TLM Thread Rolling Machines

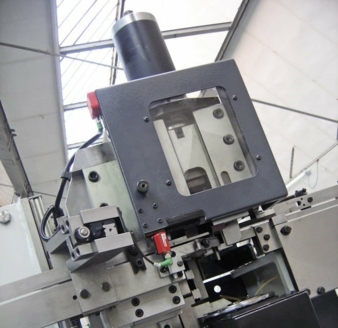

What sets TLM thread rolling machines apart from many competitors is the decision to avoid placing electronics in a crucial area like the screw insertion between the dies.

This choice aligns with the entire manufacturing philosophy of this Italian company, which has been producing thread rolling machines and special-purpose machines for over 45 years, always tailored to the need of their customers. TLM has a long history of success in modular, multi-function machines, which remain the best example of flexibility in meeting the most diverse production needs.

A Design Choice for Longevity

The precision in constructing the machine head—where all mounting surfaces are ground, along with the sliding components—combined with the rigidity of the reaction block under load during the threading process, ensures both accuracy and repeatability in achieving the final product.

This is easily confirmed by the stability and consistency of the force and deformation monitoring curves, which do not require overly tolerant settings during process supervision.

Modular Systems

Another technology that TLM has developed in recent years is the modularity of its thread rolling machines, allowing them to function as multi-purpose systems by integrating additional processing units alongside the roller system.

For example, it is possible to perform operations such as pointing, washer assembly (single or double), or even combine a rotary machine module with the thread rolling-flat dies machine.

These modules consolidate all necessary machining steps into a single pass and can also operate in a bypass mode, deactivating unused modules. The result is unparalleled efficiency in terms of time, space, and logistics.

Overhauled or Upgraded Machines

TLM thread rolling machines are built for longevity, always capable of being overhauled and upgraded. Even on older machines, updates can be implemented, such as software integration, electronic devices to assist operators, or connectivity with the company’s management system.

High-quality thread rolling machines—even from other brands—can be adapted to new machining processes and incorporated as modules in multi-function machines. In practice, a refurbished machine remains mechanically indistinguishable from a brand-new one.

TLM has extensive experience in upgrades, including micron-precise slide positioning during setup or pulse-driven micro-adjustments for size changes.