12/03/2021 – Wire processing / weaving

Weaving machines for high-quality mesh and fabrics

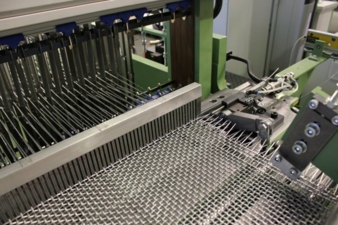

The “Jäger” metal wire weaving machines of Schlatter are designed for highly efficient production of the highest-quality fabrics. The machines are characterised by their operator convenience and easy maintenance.

Schlatter Group is known globally as a leading system provider in the wire industry. As a specialist in resistance welding systems, the company has also a complete range of weaving machines for all types of metal wire fabrics, screens and meshes under the “Jäger” brand.

The Jäger metal wire weaving machines of Schlatter are designed for highly efficient production of the highest-quality fabrics. The machines are characterized by their operator convenience and easy maintenance. The large number of peripheral devices complete the necessary equipment for economic production of metal wire fabrics.

Screen assembly machines type “RG” and “GD”

The screen assembly machines of the type “RG” and “GD” are very robust weaving machines and cover the entire market of heavy sieve fabrics. They enable the production of different screen geometries in small to large lot sizes at competitive prices.

For example, Schlatter delivers automatic screen assembly lines, consisting of screen assembly machine and weft wire crimping machine for the economic production of larger production quantities. Semiautomatic screen assembly machines with manual weft insertion complete our production program for smaller lot sizes and the production of single items.

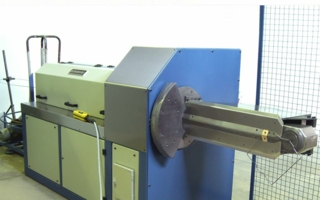

Wire crimping machines

The wire crimping machines “KM200”, “KM320” and “KMSS” are the right complement for the optimum preparation of the warp and weft wires for the Jäger screen assembly machines.

Wire weaving machines type “BD”

The wire weaving machines of the BD series are ultramodern band gripper weaving machines and cover a large part of the wire fabric market. From standard fabrics to medium heavy fabrics to heavy fabrics, Schlatter offers under the brand Jäger the corresponding machine optimized for the product.

The advantages of the machine result from the wide application range for the processing of a great variety of materials. From iron, copper, brass, bronze, stainless steel, aluminum to platinum, they can all be woven on these machines.

The fabric pattern (plain fabric, three-shaft to five-shaft twill wire cloth) is created by externally arranged positive cam motion or AC servo dobby. The weft insertion is effected by a singlesided band gripper system driven by an AC servo motor. The beat of slay is done by double cam discs. With the “BD100” and “BD520” by direct drive, with “BD600”, “BD710” and “BD800” by additional toggle lever system. The warp let-off is controlled electronically by an AC servo motor, while the warp tension is displayed digitally. A 3-roll take-up system with separate central winder or alternatively the take-up roll provides optimum and slide-free cloth take-up. The drive is effected by an AC servo motor. The drive of the BD600, BD710 and the BD800 is effected by a three-phase motor with pneumatically activated clutchbrake combination. The BD100 and BD520 have a direct drive. Whichever fabric you want to produce, fine fabrics, medium heavy fabrics, or heavy fabrics, as plain fabric or twilled weave, Schlatter Deutschland configures the optimum machine for all demands.

Schlatter Industries AG

Brandstrasse 24

8952 Schlieren, Zürich

Switzerland

Contact person is Roger Seliner

Tel.: +41 44 7327111

info@schlattergroup.com