23/04/2024 – Wire manufacture / Casting

New “RIC 400” model, break-ring, continuous casting technology

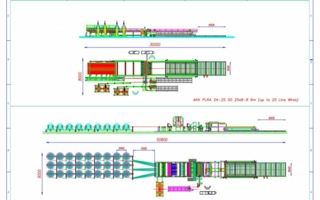

At “wire 2024”, Rautomead introduced their new “RIC 400” model, break-ring, continuous casting technology which has been developed to process cobalt alloy, nickel alloy and iron alloy wire rods from 2.5mm to 50mm diameter.

The “RS” range of graphite furnace continuous casting machines is made for the manufacture of extra-low oxygen content CuOF rod and for production of high-quality conductor alloy rods such as CuMg, CuSn and CuAg for signal data transmission wires and for railway contact and catenary wire applications.

The patented pulse motion control offers users the ability to alter and adjust the casting sequence and speed according to the alloy and rod diameter being produced. Optimal settings may be stored in the PLC memory to ensure consistent production parameters from cast to cast.

Rautomead also promoted its (patented) “RSL” sealed lid continuous casting technology, designed for processing progressive alloy rods such as copper chrome zirconium for subsequent manufacture of welding tips and small diameter drawn wires. This fully enclosed furnace features multiple, independently controlled, feed mechanisms which deliver cored wire and CuOF rod to the furnace to match the melting casting output rate whilst maintaining precise alloy composition.

Sample coils for any of the above materials can be manufactured to order and produced on continuous casting equipment installed at the Rautomead facility in the Scottish Dundee.

wire China 2024, booth E1 E41

Rautomead Limited

Nobel Road, Wester Gourdie Industrial Estate,

Dundee DD2 4UH Scotland/U.K.

Contact person is Jan Barclay

Tel.: +44 1382 622341

jan.barclay@rautomead.com

www.rautomead.com