20/12/2022 – Development and prototyping within shorter time frames

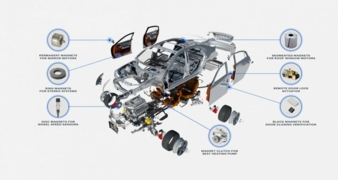

Customer-specific magnets for the automotive industry

Finding the right magnet for an electric motor, actuator or sensor can be a difficult and time-consuming process for automotive suppliers. In addition to supplying magnetic components and assemblies, Goudsmit Magnetics based in Waalre, also offer services that speed up the time-to-market for automotive manufacturers.

At the “IZB” in Wolfsburg the company demonstrated its knowledge of magnetic calculations, FEM calculations and 3D simulations that contribute to the development of a magnet or assembly that not only meets all requirements but, even before the prototyping phase, provides certainty about the correct operation.

Magnets are present in various places in cars, including the gearbox, sensors, brakes, water pump, engines, ignition coil and start generator, and in the currently widely used 'lane departure warning', which emits a warning beep or vibration signal when the vehicle strays off the road. Magnets play an important role in these critical safety systems. The quality of magnets is essential to guarantee optimal operation.

Magnetic measurements and quality control measurements are an important part of determining the quality of a magnet. These measurements provide automotive suppliers with guarantees and are a standard part of the IATF16949 process. The CPK value that results from these measurements, among others, is part of the statistical process control and says something about the way in which a magnet supplier controls its process. The higher the CPK value, the better it is. It makes the statistical chance of failure of products such as motors, actuators or sensors negligible. Moreover, since the output control of the magnet supplier is also the input control of customers, this also reduces the chance of failure of once delivered cars, machines or systems.

Using FEM simulations, engineers and product developers have a 3D visual oof how the product behaves within a magnetic system. For example, in terms of the depth of a magnetic field or magnetic flux density on another -ferromagnetic- object. This not only validates the overall performance of a component, but also shows its magnetic performance. In this way, it is possible to optimise product performance, resulting in the best possible solution for a specific application. Such simulations accelerate the development and prototyping process because the shape, grade and size of a magnetic component can be quickly determined.

Goudsmit Magnetics Groep BV

Prunellalaan 3, 5582 HB Waalre, The Netherlands

Contact person is Marc Teeuwen

Tel.: +31 40 2213283

magnets@goudsmitmagnets.com

www.goudsmitmagnets.com