14/05/2021 – E-Xhead presents new patented product

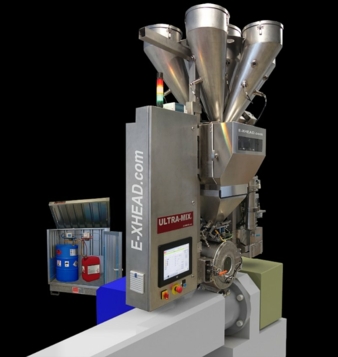

“Ultra-Mix” one-step process compounding unit

Traditional XLPE cables are produced with ready-made compounds from various suppliers. These compounds have predefined recipes of base LDPE, Silane or Antioxidant, and Peroxide. “Ultra-Mix” has been developed, for combining separate compounds online during extrusion.

Online compounding offers improvements in several aspects. There is a wide range of suppliers offering base LDPE grades for cable insulation without Silane or Peroxide and antioxidants. Customers have large freedom of choice. Traditional XLPE compounds are limited to using chemicals that are solid at room temperatures, otherwise, the compound would suffer from chemical sweat out. Shelf life makes storing premix compounds a concern.

The use of online dosing removes some of these restrictions and gives the cable manufacturer a wider selection of Silane or Peroxide and antioxidants. Online dosing offers a significantly longer shelf-life. Using alternative peroxides can even result in increased extruder outputs and longer production runs.

Our is a system for both Silane or Peroxide and Antioxidant dosing. The system consists of one to seven feeders with gravimetric measurement for accurate dosing. When different solid compounds are ready as a batch, Precision injection of Silane or Peroxide and Antioxidant is effectuated. While Liquid and Solid are mixed next batch is under preparation.

E-Xhead extrusion SA

Tel.: +41 21 8621316

www.e-xhead.com

Key feature of “Ultra-Mix”

– Can be simply installed on any extruders within one day.

– The system is independent of the extrusion line PLC, therefore no requirement to connect the unit to the extruders line control system.

– The system can work up to 7 solid compounds + 2 liquids (Silane) or (Peroxide and Antioxidant).

– Very high mixing precision of solid + liquid.

– The software can store more than 500 recipes

– The system is certified ATEX-95

– Automatic Silane Safety storage cabinet and pumping system.

– Very high savings on extrusion compounds.

– Low maintenance.