10/02/2020

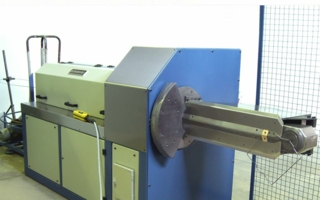

Eurobend presents at “wire” the “PL AKK” series

The “PL AKK” sets new standards in mesh production. The Avant-Garde concept eliminates all idle times and increases significantly the productivity in comparison to conventional welding lines.

All advantages from off-coil and pre-cut welding machines and more, are combined in one machine. The machines of the PL AKK series are capable of producing large and small batches-orders consecutively without any downtime. The concept behind the AKK series allows automatic mesh spacing and dimensions changes, making it the only flexible high production coil-fed mesh welding line, as it can produce all mesh types instantly without any adjustments. The double line and cross wire de-coiling station replaces the non flexible arrays of coils of the conventional mesh welding machines. The PL AKK machines have minimum floor space requirements. No downtimes when changing wire coils, wire spacing or mesh dimensions. Furthermore, the unique wire feeding system ensures diameter changes in a fraction of time in comparison to the conventional mesh welding lines, allowing multiple diameter changes in one shift (or day) without wasting time and production. The patented Automatic Wire Orientation System (AWOS) allows the use of a high speed roller straightening module for line wire feeding and absorbs all straightening imperfections from the roller straightener. The PL AKK machines are available in versions, processing diameters up to 6mm, 8mm, 10mm and 12mm coiled or spooled material.

Eurobend GmbH

wire 2020, hall 15 booth E 26

Tel. +49 911 9498980

www.eurobend.com