14/11/2025 – Steel cable stranding equipment

The future of stranding is here

Eurodraw Wire Equipment Srl, designer and manufacturer of stranding equipment, has once again raised the bar with the launch of its latest innovation: the “DTUF 900/38” double twist strander.

Engineered for precision, efficiency, and sustainability, this highly technological machine represents a decisive step forward in steel rope production.

Unmatched production capabilities

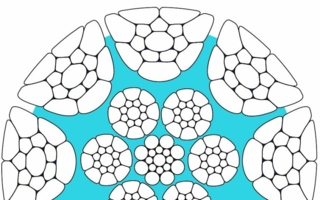

The “DTUF 900/38” is designed to produce ropes up to 8.00mm in diameter and composed of up to 37 wires while “DTUF 1250/38” is designed to produce ropes up to 10.00mm in diameter and composed of up to 37 wires offering unprecedented flexibility in product range. Thanks to its double twist technology, the machine reaches production speeds exceeding respectively 1,800 and 1,600 twists per minute – a performance several times faster than conventional tubular stranders of comparable spool size. Even more remarkable, this is achieved with a configuration that is compact, more affordable, and far less power-demanding than traditional solutions.

Intelligent wire payoff and energy efficiency

One of the standout features is the motorized filament payoff system, capable of handling 38 spools up to 1t each. Beyond its impressive capacity, it ensures extremely precise wire tensioning, adjusted directly from the operator console in just a few clicks. This system not only improves product quality but also introduces a clever energy-saving mechanism: during normal operation, the payoff motors primarily function as brakes, generating power instead of consuming it. The result is a substantial reduction in overall energy requirements – a benefit both for manufacturers’ bottom lines and for environmental sustainability.

Superior strand uniformity

The “DTUF 900/38” also incorporates two over-twisters, strategically positioned at the machine entry and within the take-up unit. The first pre-forms the strand, ensuring each wire has the correct length, while the second closes the strand to achieve a perfectly uniform and smooth final product. This innovation guarantees the highest levels of consistency and mechanical integrity across all production runs.

Industry 4.0 integration and predictive maintenance

As part of Eurodraw’s forward-looking strategy, both the “DTUF 900” and “DTUF 1250” models are fully Industry 4.0 compliant. The machine is “connected” and capable of transmitting real-time production data to a factory-wide supervision system. Integrated predictive maintenance software further enhances reliability by notifying operators of service intervals, thereby ensuring maximum efficiency and longevity over many years of continuous operation.

A leap into the future of stranding

With the “DTUF 900” and “DTUF 1250”, Eurodraw Wire Equipment confirms its reputation as a trailblazer in the wire and rope industry. Combining high productivity, energy efficiency, compact design, and advanced digital integration, this machine is not only a technological breakthrough but also a competitive advantage for manufacturers seeking to increase output while reducing costs and environmental impact. The future of stranding has arrived – and it twists faster, smarter, and greener than ever before.

Eurodraw Wire Equipment is one of the leaders in steel cable stranding equipment and is now proposing the new, highly technological “DTUF 900/38” double twist strander. This machine is designed to produce ropes up to 8.00mm in diameter and composed by up to 37 wires. The machine features a number of innovative features such as a motorized filament payoff that can carry 38 spools up to 1t capacity and ensure extremely precise wire tensioning. The wire tensioning is adjusted directly from the operator console in just a few clicks. Not only this payoff carries huge wire loads and ensures precise wire tensioning, but can, at the same time reduce significantly the line power requirements as the motors are mainly working as brakes during the normal functioning of the machine, hence generating power and reducing overall power consumption.

The double twist technology allows for extremely high production speed, and the “DTUF 900” can achieve an operating speed that exceeds 1,600 twists per minutes which is several times faster than a conventional tubular strander with similar size of spools, but is also several times less expensive and significantly less power demanding, all this is a much more compact configuration.

Another interesting feature are the two over twisters that are located at the machine entry side and inside the take-up. The first unit is designed to pre-form the strand so that each of the wires that are forming the strand have the correct length, and the second unit is designed to close the strand making it absolutely uniform and smooth.

All Eurodraw machines are now industry 4.0 compliant and are totally “connected” machines which can provide all production information to a factory integrated supervision system. A predictive maintenance software ensures that the maintenance intervals are notified so that the machine can be operated at its maximum efficiency for many years.

Eurodraw Wire Equipment S.r.l.

Via Camillo Chiesa, 19/21

20005 Pogliano Milanese, MI/Italy

Contact person is Alberto Cervino

Tel.: +39 02939631

info@eurodraw.com

www.eurodraw.com